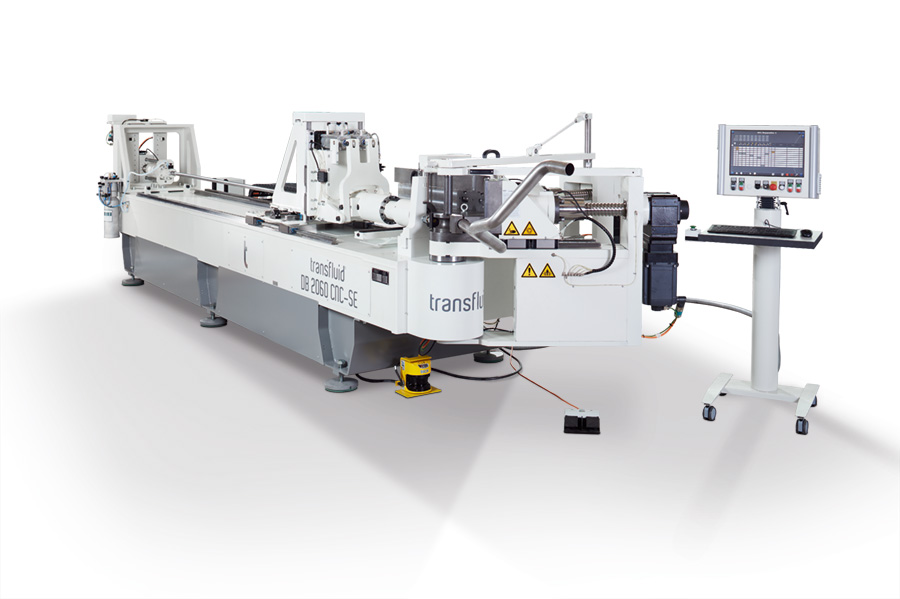

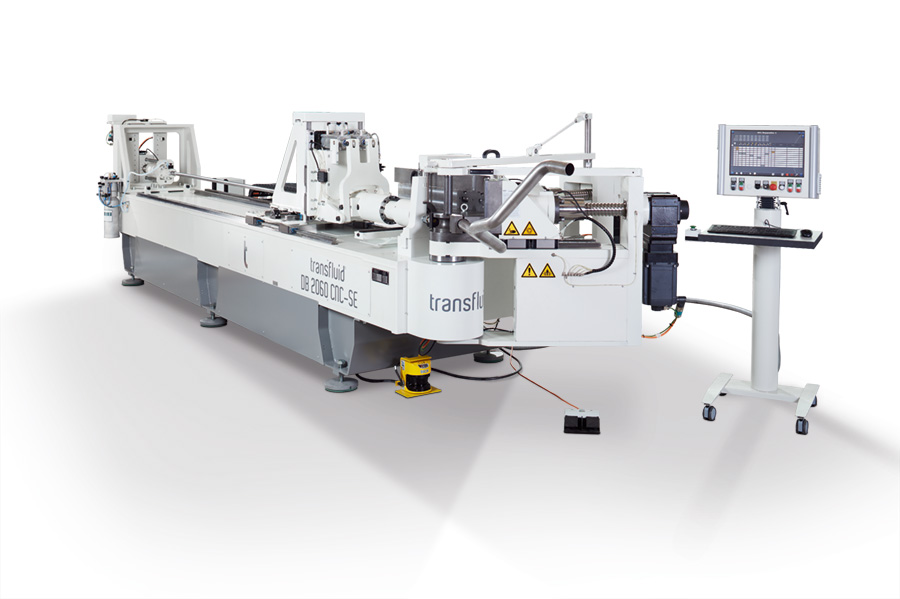

Safety is an issue that is extremely important in the aviation and aerospace industry, perhaps more so than in any other industry, and therefore the demands are very high, also on tube processing, as managing director Stefanie Flaeper explains: “There is often demand for fast production processes of small batches of complex components, of course. In addition, high and ultra-high strength materials are an important matter for tubes that are more lightweight and that can be subjected to greater loading. What makes the development of tube processing technologies for the aviation and aerospace industry particularly interesting is that there are always new technical milestones that require sophisticated solutions.” Such as the project that the company is working on at present for a leading manufacturer of aeroplanes. The new, specially designed t bend mandrel bending machine from transfluid is capable of bending titanium, aluminium and stainless steel tubes with a diameter of up to 60mm and a wall thickness of 0.5-1.5mm. Furthermore, the design makes it possible to achieve a radius of 1xD.

Axis synchronisation through smart sequential control

Axis synchronisation through smart sequential control

The other feature that makes it special is the option to control the wall thinning. This is where safety plays a key role with regards to the later application of the processed tubes in the aeroplanes. The wall thickness has to meet the specifications after the bending too; the flow through the workpiece and its stability have to be preserved. That is why the transfluid engineers have developed the push bending option for the process. The controlled push bending is applied during the last bend through a controlled inner tube.

“All the electrical axes are equipped with servo-electrical motors and their drives can be neatly synchronized”, Stefanie Flaeper explains about the technical details. “A key benefit is the complete synchronization of all the moving axes in different sequences, which is what makes our new sequential control possible.” This separates each movement of all the axes and moves the different units at the right time. That way it is possible to gradually introduce a bend with ease and either push or slow down with the required power.

Customized storage of production data and protected retrieval

All the sequences on this innovative mandrel bending machine are easy to program. The operator can allocate them to the product and retrieve them as and when needed. In addition to the actual process the sequencing will also take into account the material, radii and manufacturing processes of the product.

All control aspects can be accessed via the network. This allows the desired geometries to be taken from the CAD software and the data from the impact test be recorded in the same way. The measuring unit can be connected to the system too, depending on the size of the lots and batches. The sequence control will also store the relevant data for the production, as defined by the customer. They can then be recalled and processed with a password and the correct authorization. Furthermore, the machine’s software and all the control components, as well as the control panel (MMI), are compatible with Industry 4.0. These particular features make it possible to set up the machine with almost no operator intervention. Tube processing improvement that is right on target for the aviation and aerospace industry.

transfluid Maschinenbau GmbH

transfluid is sought after worldwide as a partner for manufacturing tube bending machines and tube processing machines. transfluid has been developing its technologies for tube machining since 1988, so that it can provide customer-oriented, tailor-made solutions – for plant and machine construction, the automotive and energy industries, shipbuilding and medical device manufacturers.

Sourcel: WIRE AND TUBE NEWS