Visitor Registration Opens in May 2026!

Laser/punch combination machines offer fabricators more capability than previous machine generations.

Laser/punch combination machines have changed enough in recent years that if fabricators haven’t taken a recent look at the technology, they may be doing themselves a disservice. In some instances, such fabricating technology might prove to be the best bang for a fabricator’s buck.

Several advancements have occurred over the years that have helped to push the laser/punch back into the spotlight. Perhaps the most important, however, has been the emergence of the solid-state laser as the dominant laser cutting technology. Today’s combination machines now are being designed with that technology at the forefront. The days of simply adding laser cutting capability to a punching machine are coming to a close. Because of these design changes, the newer machines have much smaller footprints than previous generations of machines while demonstrating greater flexibility.

With that in mind, let’s consider the five reasons a fabricator should consider today’s modern laser/punch combination machines.

1. They Can Truly Be Self-contained Work Centers

It’s a simple question that should catch the attention of any fabricator that has struggled with sorting parts coming off a solid-state laser: What if the machine could do that for you? Punching machines have always had that luxury over laser cutting machines, but that benefit also is a part of today’s laser punch combination machines.

The machine’s software determines the best way to tackle the blanking of the part, either laser cutting or punching, and then determines into what bin the chute should deposit the part. Now the fabricator has a final part that might be ready for delivery to a customer.

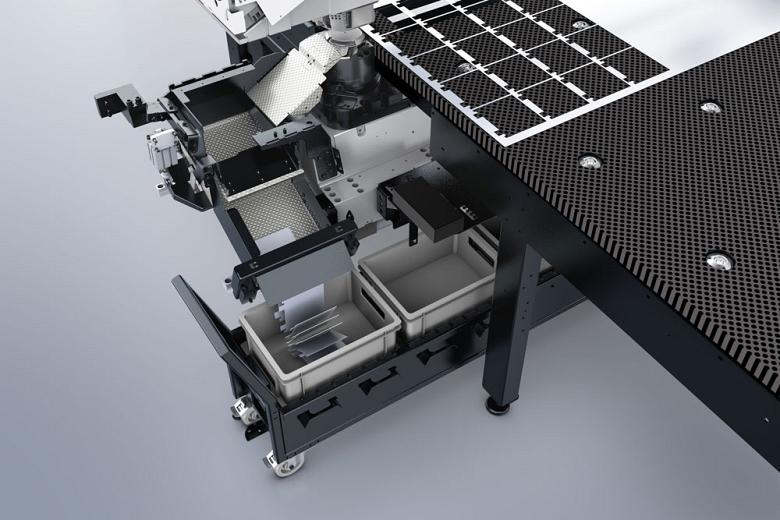

If a fabricator combines that laser/punch combination machine with material handling automation, then the shop can take the processing to the next level. The automated material handler delivers the sheet to the combination machine. The machine laser cuts, forms, and punches the material to produce the parts, which upon completion are sent down the chute to the appropriate bin (see Figure 1). The material handling system removes the skeleton and reloads a new sheet on the combination machine. The fabricator doesn’t require a parts sorter at the beginning of the shift, only someone to dispose of the skeletons.

With advanced engineering work being done, shops won’t have to wait long before automated stacking of these final parts coming off a combination machine is possible. These types of systems will be especially suitable for fabricators looking to maximize labor resources.

2. They Are Designed to Work Intelligently

Advanced control software and the increased use of sensors have led to machine tools that are much more reliable and efficient than their ancestors. This is good news for metal fabricators looking to maximize uptime in the face of a robust manufacturing economy.

For example, with punch monitoring, a sensor checks to see whether a hole has actually been punched into the sheet with a tool’s last stroke. If the hole is clear, the control software will allow the machine to continue with the job. If the hole isn’t clear, the machine stops until the problem is resolved. This early warning system not only protects the fabricator from having to redo parts, but it also notifies the operator that a punch break is likely and needs to be addressed.

Sensors also are used to detect part ejection down the chute and into the bin. Again, if the sensor on the chute detects the part passing through, the trap door closes and the combination machine can continue processing. If it does not sense the part, the machine stops.

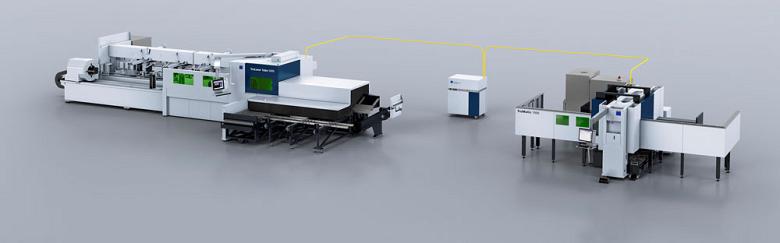

Figure 2

A fab shop may choose to run two separate operations from one solid-state laser generator. A laser/punch machine and a laser welding cell make for a good combination in this scenario.

3. They Can Be Networked to Expand a Fabricator’s Capability

The solid-state laser generator is designed so that one power source can be networked to two machine tools (see Figure 2). It provides a fabricator with the opportunity to make a cost-effective investment in multiple capabilities without the requirement of purchasing a second laser power source.

For example, a fabricator can operate a laser/punch combination machine and a laser welding device with one solid-state laser processing unit. It should be noted that both machines could only be operated simultaneously if the combination machine was strictly punching at the moment the laser welding cell was drawing power off the solid-state laser power source. The switching between the two cells takes place quickly, even during sheet movements on the combination machine.

This type of network ensures that a fabricator gets maximum usage from the laser generator. After all, a laser/punch machine is going to be punching a good percentage of the time, leaving that laser power source ready for some other task.

4. They Can Process More Materials Than Previous Generations of Machines

It’s no secret that CO2 laser cutting machines had difficulty with reflective materials such as copper and brass. While the technology did well with other, less-reflective materials such as mild steel, aluminum, and stainless steel, it just didn’t fare as well with the more reflective materials, which also happened to be poor absorbers of infrared laser light.

The emergence of the solid-state laser changed that. It has a wavelength about 10 times smaller than the 10.6-μm CO2 laser beam wavelength. The reflective materials don’t reflect the smaller-wavelength laser as much as the CO2 laser; as a result, the laser energy is absorbed more easily. Also because the shorter wavelength can be focused into a spot that is around one-tenth the diameter of a CO2 beam, the solid state laser has a higher power density, making metal penetration easier. This translates into effective cutting of copper, brass, silver, and even gold.

5. They Eliminate Secondary Processes

Source: FMA