Visitor Registration Opens in May 2026!

.jpg)

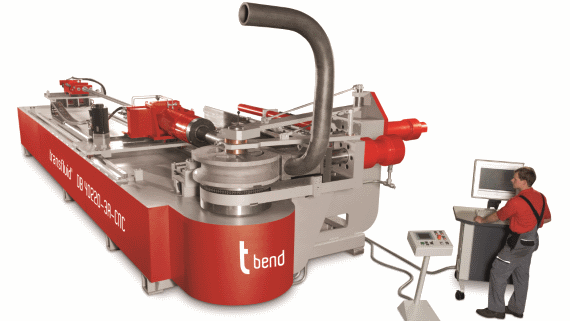

The pipe bending machine DB 40120-CNC-VE by transfluid changes tools automatically. ? Transfluid Maschinenbau GmbH

It is possible to achieve much simpler and much cheaper tube processing, when the flanges are welded onto the straight tube beforehand, because the welding process is considerably faster at that stage. With the internal connection to the CAD programs, the ‘t project’ bending software can process the isometrics immediately.

Better bending of tubes with flanges with the transfluid software

The fast setting-up of the machine, at times in less than 10 minutes, also plays a crucial role. Equipped with a fully automated CNC control system, the transfluid units can process tubes with thin and thick walls and made of any material, even with radii of 1.5 x tube diameter or more. These tight bending radii are achieved with unrivalled minimal thinning of the tube walls. This leads to benefits also in terms of space on board the ship.

“Saving time and money are aspects that we make possible for this industry, when it comes to tube processing”, says transfluid Maschinenbau GmbH director Stefanie Flaeper. “Our ‘t bend’ CNC bending machine has replaced the need to weld bends onto large tubes a long time ago, as it lowers the production costs.” In addition to that, the bending systems save up to 60% of the production time for tubes with a diameter up to 400mm.

Bending tubes with a diameter of up to 400mm faster

Mobile measuring tools acquire data on-site, for instance in order to measure template tubes accurately. In addition to that, transfluid offers the option of tube end-forming processes with the rotary tube forming UMR ‘t form’ machine. For instance, it is possible to introduce flared flanges economically and subsequently bend the tube.

Digital solutions are required by the international shipbuilding and off-shore industry for efficient planning of their resources and processes. To support that, the high-tech machine manufacturer transfluid combine their bending technologies for large diameter tubes with online networking aimed at practical applications, as with the ‘t project’ software calculating beforehand the exact orientation of the flanges, when bending straight tubes with welded flanges.

Cheaper and faster bending of large tubes with the 't bend' tube bending technology from transfluid. ? Transfluid Maschinenbau GmbH

Flanges can be chosen from a database and integrated in the isometrics, also in terms of bending technology. “With the directional bending of the flanged tubes our solution is able to improve the flexibility of the manufacturing. The processes clearly become simpler”, explains Stefanie Flaeper.

‘t project’ for mobile use on board

The tablet version of the ‘t project Draft’ software offers greater freedom for on-site practical applications. It allows the user to acquire data with a very light, portable measuring system. It is thus possible to collect data, for instance for connector tubes, both the geometries of the process, as well as the flanges and the position of the flanges. Time savings are particularly significant for this aspect.

As the mobile version, 't project Draft' contributes to more time-efficient and more flexible tube manufacturing. ? Transfluid Maschinenbau GmbH

The process of measuring on board only requires a few minutes, even for more complex tubes with flanges. All the data is acquired digitally, documented and the data can be transferred online and be available to the technical office, as well as the bending machine. Once a tube-part has been completed, it can be measured once again, in order to guarantee a smooth installation. And here is an additional time benefit: whilst tubes are processed with the measurement data that was provided, further measurements can be taken on board.

Effective forming of tube ends

A key aspect of tube processing in the shipbuilding industry is the forming of tube ends, like the forming of flared flanges on the tubes. With the rolling UMR ‘t form’ machine it is possible to shape tubes with diameters up to 325mm. Almost tool-independent, it uses a controlled shaping cone, which can be programmed freely during the task.

Another interesting shaping option is the cylindrical expansion of tube ends, in order to connect two tubes. The transfluid solution to this challenge is suitable for tubes with a nominal size up to 250. The traditional practice in shipbuilding of welding with two seams on each connection sleeve for large nominal sizes is now redundant.

transfluid will be SMM 2018, hall B2.3G, stand 324, to present its high-tech solutions for the processing of tubes in shipbuilding.

Source: Tube