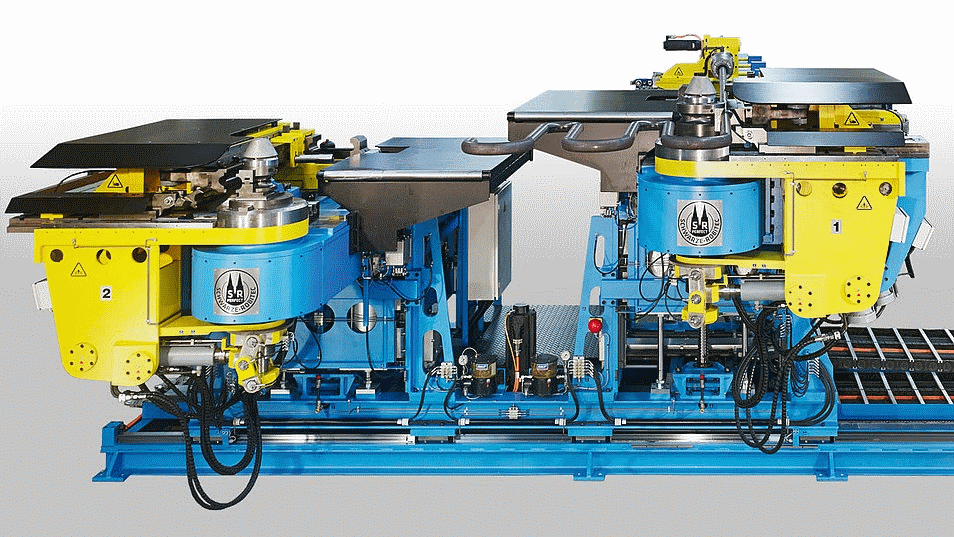

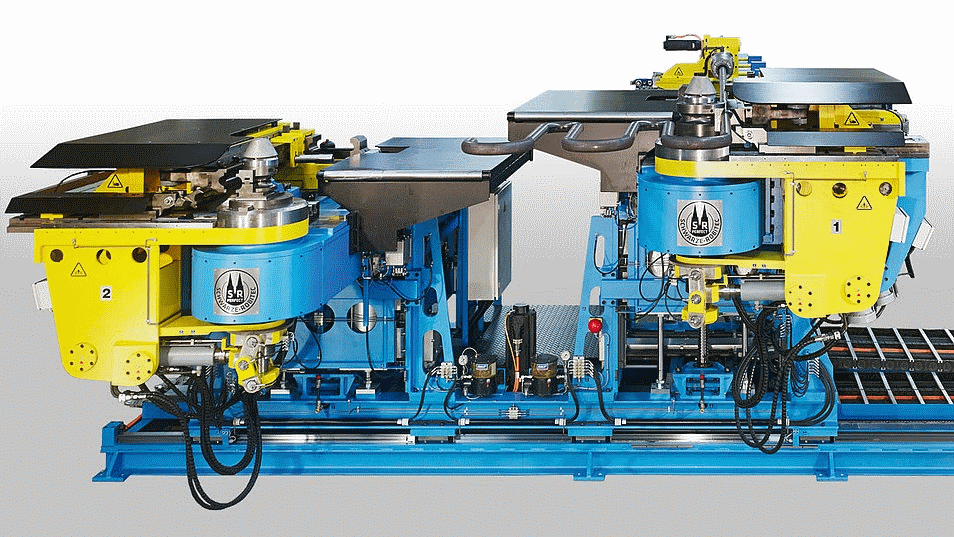

Schwarze-Robitec has delivered two of its booster bending machines for use in Vietnam's boiler and power plant industries. ? Schwarze-Robitec GmbH

Schwarze-Robitec has delivered two of its booster bending machines for use in Vietnam's boiler and power plant industries. ? Schwarze-Robitec GmbH

Schwarze-Robitec has delivered two of its booster bending machines for use in Vietnam's boiler and power plant industries. Martech Boiler Co., Ltd., an energy solutions provider, will now use a CNC 100 DB for the mandrel-free bending of thick-walled boiler tubes, and a FL 2000 for processing welded boiler walls. The machines, which are part of Schwarze-Robitec's Boiler & Power series, are specially designed for the particular requirements of boiler and power plant construction. They guarantee high-precision bending performance and are designed for years of continuous operation.

Martech Boiler Co., Ltd., is a company based in Ho Chi Minh City, Vietnam, which specialises in the production of boilers and pressure vessels for the energy industry. Its portfolio of products includes waste heat boilers and boilers for fluidised bed combustion. For years, Martech has been using a CNC 80 DB from Schwarze-Robitec to bend tubes up to 88.9 mm in diameter. Impressed by the reliability and durability of the machine, Martech has again put its trust in Schwarze-Robitec. Thanks to the new CNC 100 DB from the German company's Boiler & Power series, Martech is now able to bend – without a mandrel – thick-walled tubes up to 114.3 mm in diameter at a wall thickness of 8 mm.

One particular stand-out feature is the compactly designed construction unit of the tube boost and integrated tube clamp element, which safely transfers the boost force to the tube. This enables, for instance, the mandrel-free cold bending of very small radii up to a radius of 1 x D with minimal reduction of wall thickness and optimum ovality. The Schwarze-Robitec method surpasses the tolerance specifications for wall thinning and ovality, for example, of the European standard EN 12952 and the American Society of Mechanical Engineers standard ASME B31.1 as well as all other international norms. This means that various media can be transported in the tubes in a consistently reliable manner.

Finned walls enable effective heat exchange

State-of-the-art power plant construction would not be possible without finned walls consisting of multiple tubes welded together, otherwise known as membrane tube walls. They ensure effective heat exchange as part of a huge piping system. As part of this process, individual tubes are welded together to form bending membrane walls. They then undergo bending to align with boiler dimensions before being installed. To bend such finned walls, Martech uses the FL 2000 from Schwarze-Robitec. With millimetre precision, this machine processes entire bending membrane walls with a through-width of up to 2,000 mm in a single operation. The diameter of the tubes can go up to 70 mm and the wall thickness up to 5 mm. In addition, there is increasing demand for diagonal bending, which is something the FL 2000 is able to achieve thanks to its horizontal rollers.

The extremely powerful machines from the Boiler & Power series are able to overcome the demanding conditions which often dominate the boiler and power plant industry. They have been used for many decades throughout the world.

Source: Schwarze-Robitec GmbH

Schwarze-Robitec has delivered two of its booster bending machines for use in Vietnam's boiler and power plant industries. ? Schwarze-Robitec GmbH

Schwarze-Robitec has delivered two of its booster bending machines for use in Vietnam's boiler and power plant industries. ? Schwarze-Robitec GmbH