Visitor Registration Opens in May 2026!

Robots for bending tubes that are even more effective

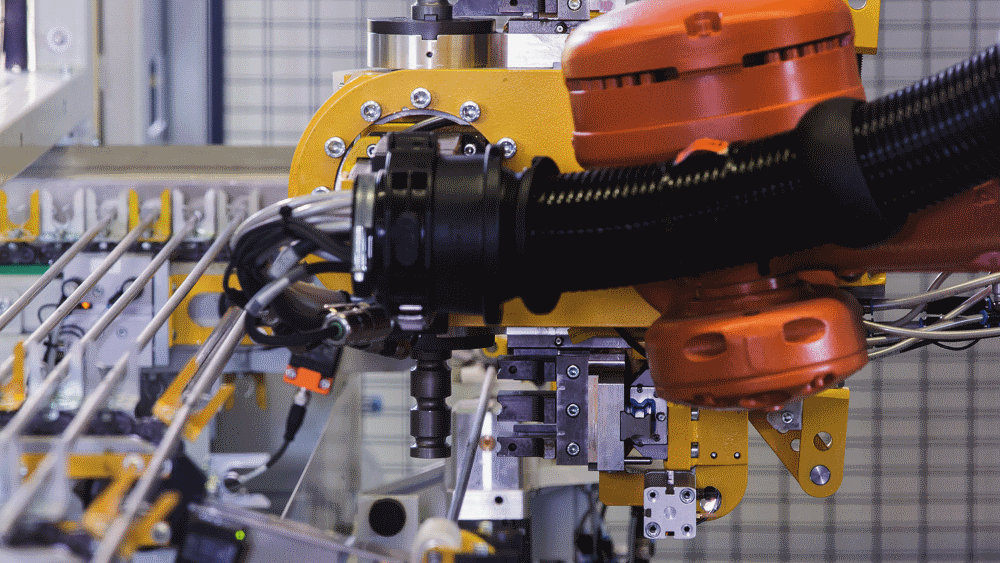

© Transfluid Maschinenbau GmbH

Robots that process tubes in an effective and flexible way have already being used for some time in transfluid’s production cells. Since the beginning, these bending systems have been capable of taking isometrics data and use them to generate bending data, without the need for separate robot programming.

The high-tech engineering company has now taken the development of its bending robots one step further and improved them again.

“We wanted a solution that was even easier to use. This applies to the programming, which has been reduced or completely eliminated”, explains Stefanie Flaeper, transfluid director. “And at the same time, we have managed to make the robots even more flexible. It was a very big challenge to significantly improve bending robots that were already working extremely well. That is why I am even happier that our team of experts have been successful.”

Synchronized and clear identification

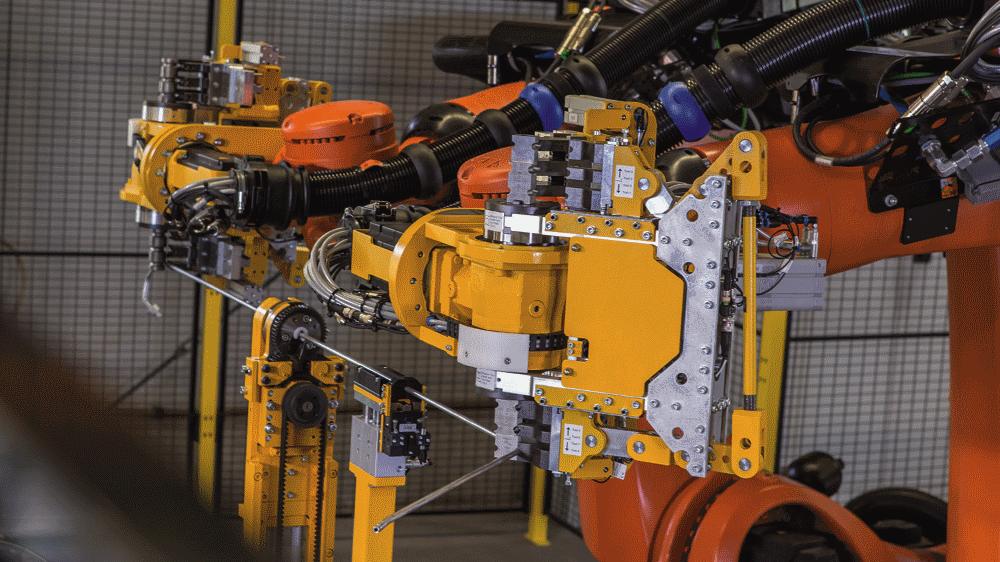

Tried and tested transfluid bending units with two robots bend long tubes from both sides. This way the tubes can be supplied already with forming or connection systems. However, it is much easier to process straight tubes in forming machines, when a bending machine can start from both sides.

“The robots are synchronized when in use. Additional fittings, like mounting and support devices, are automatically synchronized with the processing robots. The robots recognize the tubes thanks to the code on the components and they generate the bending sequence; they can also choose different radii and diameters”, says Stefanie Flaeper. It is possible to work with up to six different tube diameters without tool changing.

Expanded processing, greater output

With the new and continued developments from transfluid, each manufacturing cell with two robots can do more than just bending tubes from both sides: each of these bending robots can also work on their own different geometry. The system can therefore be used in a very efficient way and the output is significantly greater.

“With the software we have developed we have set ourselves a new goal, which is to make the processes much simpler. The bending data will be generated automatically from the coordinates, without the need to program the robots”, sums up Stefanie Flaeper.

© Transfluid Maschinenbau GmbH

Bending and Handling, without costly and time-consuming programming

The latest generation of bending robots also offers safer handling. The position where the robot grabs the tube in the magazine and the position where it grabs the tube to remove and deposit it can be retrieved from pre-programmed settings. This means that the operator has to do almost no programming of the bending program or the handling process.

It is simply retrieved from stored data. It is also possible to process components that have been bent and put aside by the robots without any problems, even if there are potential collisions, because of the long segments. This is because the last bend can be done on the “floating” tube, just above the unloading position. The whole system is managed through the bending machine controls.

This has the advantage that you can work with x, y and z data, but also with lengths and bending angles, just like with the standard bending machines. It is not necessary to have special knowledge of how to program a robot. To keep the set-up time as short as possible, the robots have preloaded settings that include the additional axes. This makes it possible for the operator to complete any tool changes in a very short time.

The robots can be positioned next to each other in specific positions. By pressing a button, the system will return to the start position. With the latest generation of tube bending robots, transfluid has once more advanced and made more efficient the possibilities of tube processing.

Source: Transfluid Maschinenbau GmbH