Visitor Registration Opens in May 2026!

TRUMPF makes inroads at German manufacturers with additive technologies

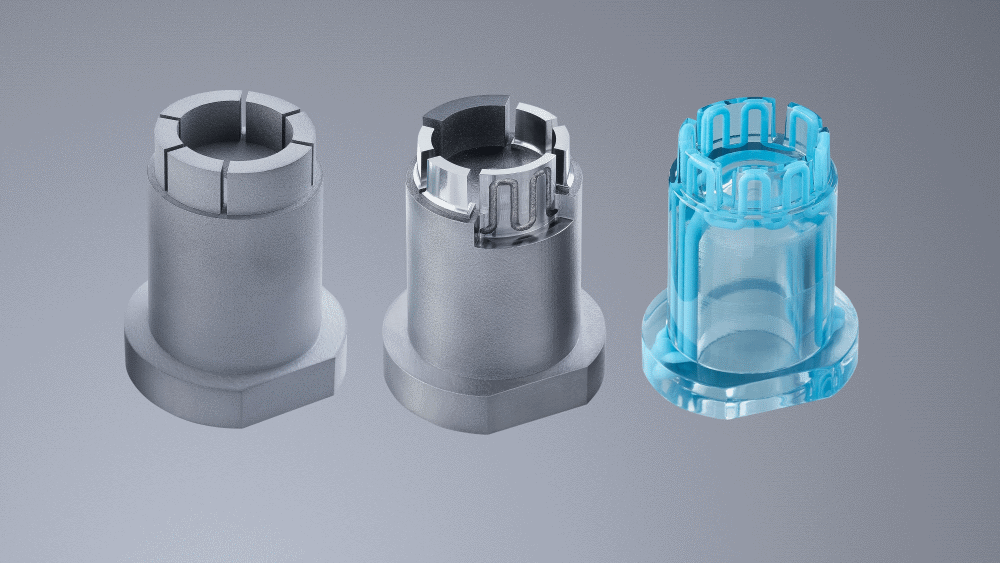

Significant improvements in cooling properties of 3D printed tools © TRUMPF GmbH + Co. KG

TRUMPF will be on hand to show companies from the tool, pattern and mold making industry how to make the most of 3D printing. One of the many benefits of additive manufacturing is the ability to make tools with near-net-shape cooling.

Tools manufactured in this way dissipate the heat generated during the production process directly at its source. This reduces cycle time and improves the quality of the fabricated parts.

Dissipating heat at its source

Producing parts by injection molding or die casting generates heat. To dissipate this heat, manufacturers equip the molds with cooling channels that help keep temperatures as stable as possible to prevent distortion of the part and similar problems.

Conventional methods such as milling, however, soon reach their limits when it comes to creating these channels. "The difficulties are particularly evident with more complex shapes: we can't get the drill into all the right places because we can't drill around corners!" says Marc Dimter, a TRUMPF industry sector manager who is responsible for tool and mold making.

In contrast, 3D printers build up the mold layer by layer, enabling the construction of cooling channels that run almost parallel to the tool wall. The biggest benefit is the reduction in cycle time that stems from faster cooling of the tool. In many cases, quality also improves because parts are less prone to distortion.

What's more, faster cooling results in more homogenous material properties in both injection molding and die casting, ultimately making parts more resilient.

German toolmakers still hesitant to adopt 3D printing

Despite these advantages, German toolmakers have been slow to adopt additive manufacturing technologies.

"Many companies lack the necessary expertise and are unwilling to make the investment," says Christoph Dörr, who also works at TRUMPF as an industry sector manager for the tool and mold making industry.

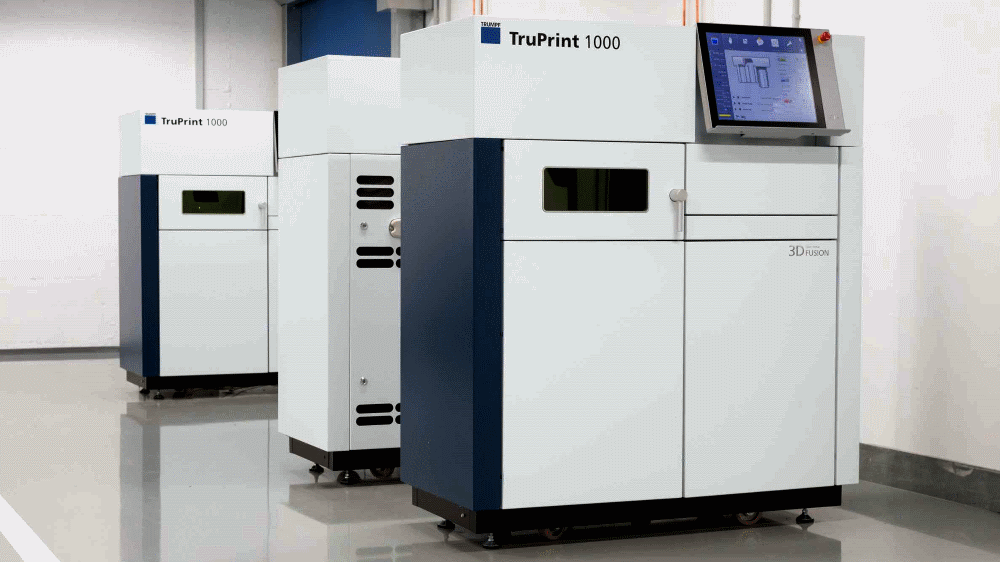

He notes that US companies that supply their molds to Europe have already built up a strong lead. That's why TRUMPF is taking the opportunity offered by Moulding Expo to showcase its TruPrint 1000 3D printer as an entry-level model.

TruPrint 1000 offers entry-level access to 3D printing © TRUMPF GmbH + Co. KG

The plug and play design of the system makes it easy to install and operate, and it is particularly suitable for small injection mold inserts such as those used for plastic connectors in the electronics industry.

TRUMPF will also be presenting a selection of 3D printed tools and molds with optimized cooling at the fair. By 3D printing a gate bushing, TRUMPF was able to reduce one customer's cycle time by almost 30 percent.

"We're hoping to inspire toolmakers to exploit the huge potential of 3D printing. That's why we also offer them training in 3D design," says Dörr. What's more, TRUMPF can supply the powder and parameters for each application directly, making it even easier for companies to adopt this new technology.

Source: Tube 2020