Visitor Registration Opens in May 2026!

Mobile system for testing composite materials with USB 3.0 uEye LE camera

The combination of two or more materials often creates unique properties. Particularly beneficial qualities of the components can be emphasized and combined. For this reason, industry likes to use composite materials. However, the in-homogeneous structure of the material must also be taken into consideration. During machining, for example, fraying and chipping can occur on bores or milled edges. The portable optical inspection system from Math & Tech Engineering GmbH with an integrated USB 3.0 camera from IDS automatically detects and evaluates specific processing errors. This ensures better reproducibility of the measurement results and enables accurate documentation.

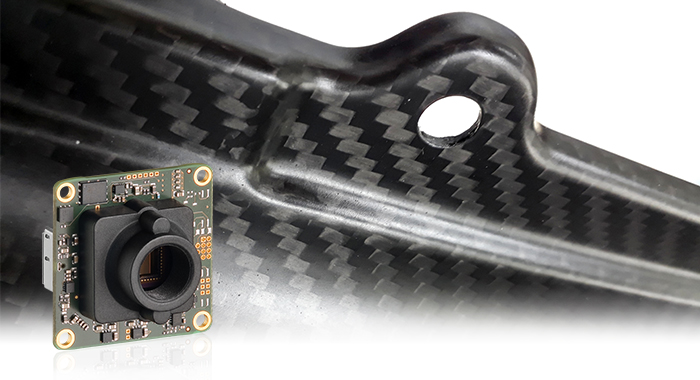

Modern compound materials are increasingly being used in a large number of manufacturing industries. As the name suggests, they consist of a plastic matrix with reinforcing fibers instead of being a single homogeneous material. These innovative materials feature completely different properties than conventional counterparts and often generate cost advantages. Examples are carbon or glass fiber reinforced plastics. The latter – often known as fiberglass – exhibit excellent corrosion behavior in aggressive environments as well as high elongation at the break point and high elastic energy absorption. This makes them a suitable material for containers in plant construction or also for boat hulls.

Modern compound materials are increasingly being used in a large number of manufacturing industries. As the name suggests, they consist of a plastic matrix with reinforcing fibers instead of being a single homogeneous material. These innovative materials feature completely different properties than conventional counterparts and often generate cost advantages. Examples are carbon or glass fiber reinforced plastics. The latter – often known as fiberglass – exhibit excellent corrosion behavior in aggressive environments as well as high elongation at the break point and high elastic energy absorption. This makes them a suitable material for containers in plant construction or also for boat hulls.

However, the special structure of the material also specifically determines the behavior of the product during machining. The very different stiffness of matrix and fiber as well as the existing fiber direction must always be taken into account, e.g. when trimming. In the case of a machining error, material defects occur. These show specific damage patterns. Characteristic features are, for example, break-outs on the brittle-hard matrix material, fraying due to incompletely cut fibers and delamination – the detachment of individual layers.

Image Processing Solution

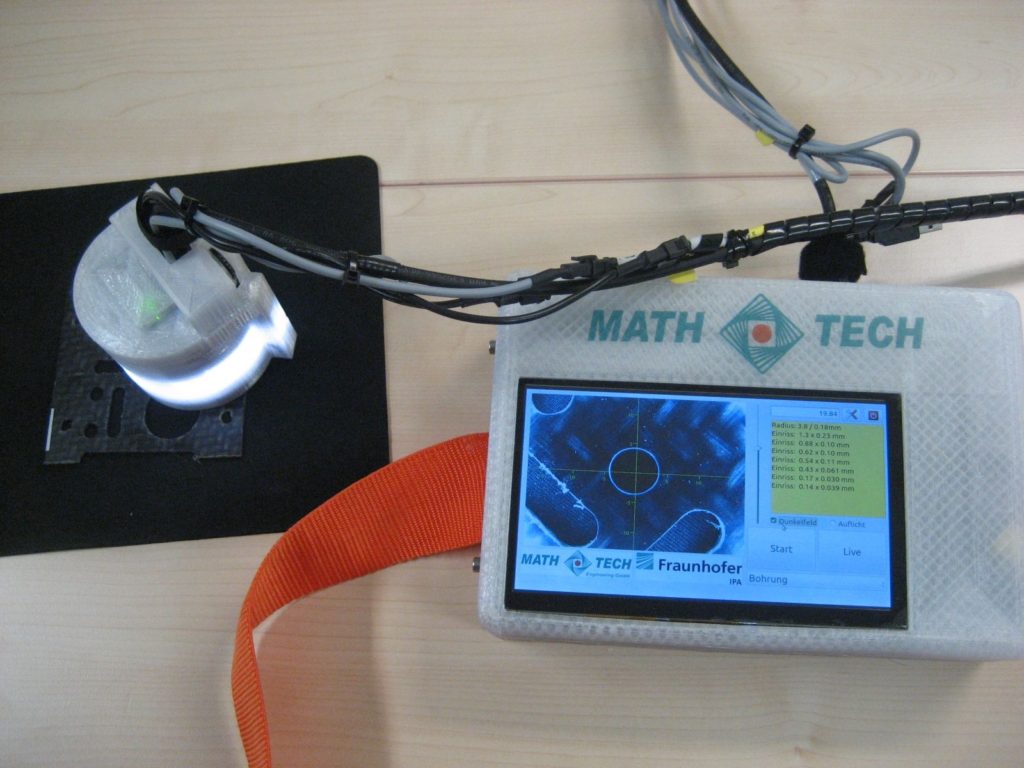

The evaluation of the machining quality of composite materials is often carried out manually by the worker, for example with the aid of boundary sample catalogues. However, this subjective assessment is time-consuming and error-prone. For this reason Math & Tech Engineering GmbH, based in Neckartenzlingen, has developed an automated optical inspection system using image processing with an integrated USB 3.0 industrial camera from IDS. Image acquisition, evaluation and result display are performed by a single portable device with controlled dark field and incident light illumination. At the same time, the tailor-made complete solution ensures comprehensive documentation of the measurement results.

The camera captures images of the surface and the processing edges of the composite materials to be tested. The system then identifies and measures all areas in which production errors have occurred. This is done with the help of algorithms developed in-house using image processing software HALCON from MVTec. Specifically, the camera image is used to identify, differentiate, classify, measure and evaluate background, material surface, processing edge and defects. The entire evaluation takes place directly on the mobile device, making it highly efficient and easy for the user to operate.

The individual fibers of the material must be clearly identifiable as a prerequisite for the identification of the defective areas. At the same time, the image must cover a sufficiently large working area. Math & Tech therefore relies on a USB 3 uEye LE board level camera from IDS with an extremely high resolution of 18 megapixels. “We chose the UI-3591LE because of its high bandwidth, simple plug-and-play functionality and compliance with industrial requirements,” says Dr. Timur Rashba, Managing Director of Math & Tech. He adds: “It also offers us the high resolution in a small space.” The company uses the existing inputs and outputs (2 GPIOs, as well as an I2C bus) to control the image acquisition by means of hardware triggers or lighting.

The uEye’s own C++ library interface allows direct control of the camera from the program, as well as direct access to the image data. This avoids waiting times from copying and loading processes. “For fast camera tests, e.g. function, trigger, GPIO, camera settings, sharpness, etc., we use the uEye Cockpit on Windows and Linux. It provides a reliable, fast plug-and-play solution. This means that the hardware can be tested independently of the program and suitable default values for the application can be easily determined,” explains Dr. Rashba.

Outlook

More and more cameras replace the human eye and algorithms take over the objective evaluation. The mobile handheld device from Math & Tech perfectly meets these requirements. At the same time, it is highly expandable, e.g. to other material surfaces and customer-specific applications. In addition to checking carbon or glass fiber reinforced plastics, it could also check metals, wood, plastic, leather or similar materials. In almost all areas, it is essential to record quality quickly and easily – be it to check your own products or to inspect received material at random or as a whole. A portable, automated system can be used anywhere and thus offers real added value for the user. Errors are reduced. Human inaccuracies avoided. All measured values are traceable and transferable at any time. Efficient and always accurate – a durable connection.

Source:Wire And Tube News www.wireandtubenews.com