Visitor Registration Opens in May 2026!

To save time, weight and costs when producing metal aircraft components, Airbus Helicopters in Donauwörth, Bavaria, part of the Airbus Group employing 7,000 staff, has recently turned to additive manufacturing.

The company not only develops and produces a range of helicopter models such as the H135 and H145, but also specialises in the manufacture of more than 4,000 doors for passenger and cargo aircraft every year.

To separate the titanium parts from their base plate rapidly, economically and without damage after they have been 3D printed, in October 2018 Airbus Helicopters purchased an automatic KASTOwin amc bandsaw from KASTO, also based in southern Germany. The machine, which is enclosed to prevent the ambient air from becoming contaminated and is prepared for connection to an extraction system, is available in the UK and Ireland through the firm’s Milton Keynes subsidiary.

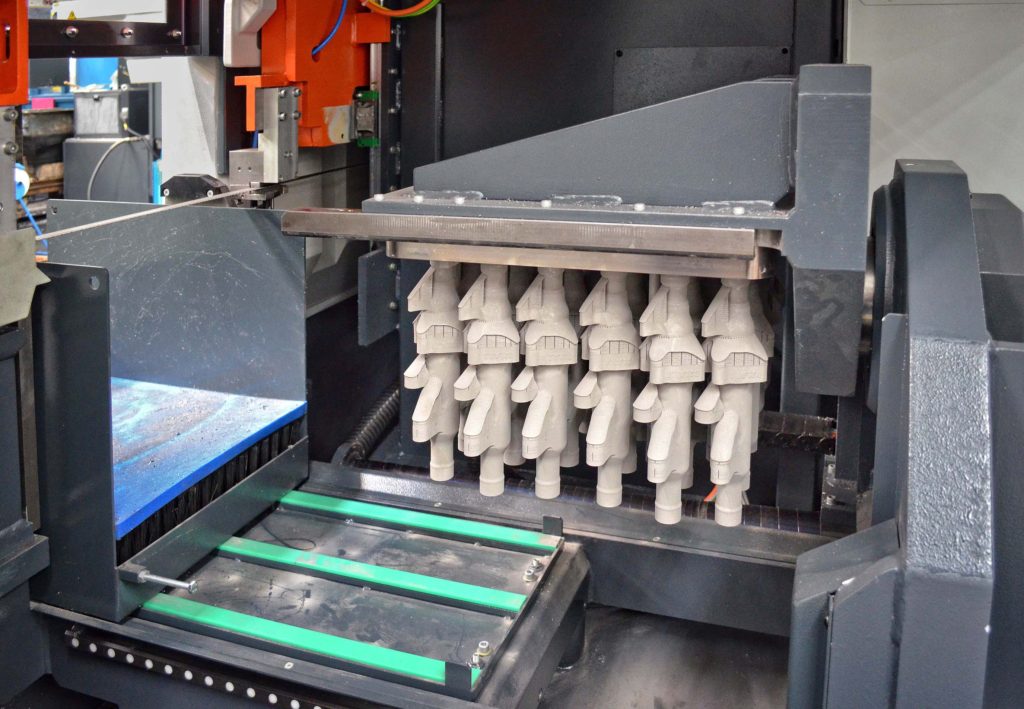

The Donauwörth factory additively manufactures titanium shafts for locking aircraft doors using the layer-by-layer powder bed method. Sixteen of the components are installed in every Airbus A350, for example. The walls of the shaft are thin and have a complex geometry, making 3D printing a particularly suitable production method. It cuts costs by 25 per cent and results in a weight saving of more than 45 per cent, or four kilograms per A350 aircraft, compared with the previous production process.

When printing of the components is finished, they must be separated from the 400 mm x 400 mm titanium baseplate, a function that the KASTOwin amc has been specifically designed to perform. The base plate with 3D printed shafts weighing up to 40 kg is transported from the 3D printer by fork lift truck to the saw and bolted securely to a clamping mechanism.

The machine door closes and the mechanism rotates through 180 degrees so that sawing of the components to remove them from the base plate is performed upside down. This design offers considerable advantages in additive manufacturing as after being cut, the parts cannot topple over or buckle, preventing the risk of damage that could lead to time-intensive reworking or even expensive scrap.

As the plate is ground flat after each build so it can be repeatedly reused, it becomes progressively thinner. So before sawing begins, an employee has to measure its thickness when clamped and enter the figure into the job wizard of the AdvancedControl CNC. The bandsaw blade, actuated by a high-precision ballscrew drive, then moves precisely to the programmed height. When cutting is complete, the shafts fall into a padded container to prevent damage and are removed through a flap.

Before opting for the KASTO machine, Airbus Helicopters conducted trials at the saw technology specialist’s premises in Achern and were impressed by the results. Bandsawing was achieved easily, rapidly, accurately and significantly more cost-effectively than by alternative machining methods such as milling or wire-cut EDM (electric discharge machining).

Additive manufacturing of other metal components is planned at the Donauwörth factory, so the KASTO saw will play an even more prominent role in production in the future.

Source:Wire And Tube News www.wireandtubenews.com