Visitor Registration Opens in May 2026!

Measurement of plastic pipes from the inside of the pipe head during extrusion

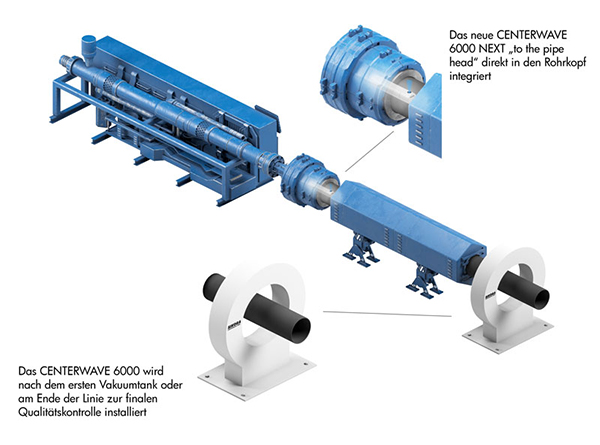

As the previous exhibitor of Tube China, SIKORA, manufacturer and worldwide supplier of innovative pipe testing and measuring technology, presents for the first time the CENTERWAVE 6000 NEXT “to the pipe head” at K 2019. Already prior to the first vacuum tank and thus, immediately after the pipe head, the system measures the decisive dimensions of the pipe from the inside at the start of the production line. For the first time, measuring values for wall thickness, concentricity, inner and outer diameter as well as information on weight per meter are available at such an early stage of the process. Thus, plastic pipe manufacturers receive the basis for a control and centering without delay, at the beginning of the extrusion process.

The CENTERWAVE 6000 NEXT “to the pipe head” is based on millimeter wave technology and measures the wall thickness distribution directly after the pipe head gapless over 360 degrees of the circumference already at the starting of the production line. A rotating radar sensor is connected with the pipe head and is positioned directly in the center of the pipe. By means of millimeter wave technology, wall thickness, diameter and concentricity are measured over the circumference from the inner side of the pipe. The measuring values are graphically visualized.

In combination with the proven CENTERWAVE 6000 after the first vacuum tank, the warm measuring values as well as the already stable and final cold values of the wall thickness of the pipe are measured by the CENTERWAVE 6000 NEXT “to the pipe head”. These are controlled without delay to the minimum permitted nominal value at optimum concentricity. The interaction of both systems allows for the compensation of typical plastic pipe dripping effects (sagging).

The operation of the systems is intuitive and easy without any prior knowledge about the material and its high frequency characteristics. Precise measuring values are generated, only the entering of the nominal value is required if this has to be controlled. When controlling the wall thickness to the minimum value, the software automatically determines the necessary addition to the nominal value.

By using the CENTERWAVE 6000 NEXT “to the pipe head“, the start-up process for the extrusion of a pipe is significantly facilitated and simultaneously shortened. Thus, the production process is optimized, the highest quality of the pipe ensured and costs are saved. A fast Return on Investment (RoI) is guaranteed.

Except for K show, SIKORA attends tube & pipe trade fairs to showcase their pipe testing, measuring, control, inspection, analysis and sorting systems as well as their permanent availability. Industry colleagues and buyers are looking forward to their participation in Tube China 2020, Asia's leading tube and pipe exhibition again. The event will take place on 23-26 Sept. 2020 in Shanghai China.

Source: SIKORA AG