Visitor Registration Opens in May 2026!

Despite the political wrangling over the past few years and the consequent business uncertainty, the UK remains a strong and successful market for Kasto, according to Ernst Wagner, who runs the German manufacturer’s subsidiary in Milton Keynes. Over the years, Kasto has sold more than 1,400 bandsaws and circular saws into the UK and southern Ireland, from job shop models to production saws for processing all types of material from aluminium to nickel alloys and titanium.

In addition, in the same markets the company has an installed base of over 30 automated material storage systems, designed to move long stock and sheet metal from the floor or cantilever racking into space-efficient, computer-controlled towers. Systems range from stand-alone units to integrated storage facilities with full material traceability. All promote high density 3D storage as well as operator safety and efficient manufacturing through timely delivery of material to production machines.

Mr Wagner commented, “The economy of the United Kingdom is highly developed and market-orientated. It is currently the sixth largest in the world measured by gross domestic product (GDP) and ninth largest for manufacturing, which accounts for 11 per cent of gross value added (GVA) and employs 2.7 million people directly plus many more in supply chains and services.

“Its crucial importance and contribution to the economy is the reason Kasto in the UK is supporting the motto ‘Make it in Britain’ as we go into the New Year and in the run-up to the MACH 2020 show in Birmingham next April.

“Admittedly the machine tool sector’s performance has softened of late, but it is happening globally. Whenever it comes out of a downturn it is always stronger, leaner and achieves a higher turnover when it reaches the next peak. Hopefully 2020 will show the first signs of that process, aided by the legendary grit of the British people.”

He added that it is Kasto’s intention to be part of the turnaround and went on to outline what benefits the company is able to bring in terms of practical solutions.

First is service and support for all Kasto customers, existing and new, throughout Britain and Ireland, underpinned by six strategically located service engineers. He pointed also to the augmented reality remote troubleshooting and maintenance system, VisualAssistance, which can often make an engineer’s visit unnecessary. Until now it has been conducted online from the German headquarters and factory, but the same service is now being phased in via the Milton Keynes subsidiary following the company’s recent move into new premises. Advanced technology is the other cornerstone of Kasto’s provision and there are many examples. One is the development of KASTOwin amc, an innovative, automatic bandsaw designed to increase productivity in the additive manufacturing sector. The saw incorporates a 180-degree turning device that allows 3D-printed parts on their build platform to be inverted so that the components fall into a container after they have been sawn. Efficiency, reliability, precision and safety are increased and upside-down sawing prolongs blade life, as wear on the teeth is reduced because swarf also falls away under gravity, so less is drawn through the cutting channel.

Another innovation is the invention and patenting of KASTOrespond, which in tandem with the use of ballscrew-driven rather than hydraulic downfeed allows bandsaw frame and blade oscillations to be sensed and managed. Automatic optimisation of the cutting parameters including control of the downfeed pressure minimises vibration while at the same time maintaining a constant chip load throughout the cut, irrespective of material cross section.

The system is used on KASTOwin and KASTOwin pro bandsaws, as well as on the latest KASTOtec, which are all designed for cutting with tungsten carbide tipped (TCT) blades but are equally capable of using bimetal blades. Employing this technology, the latest cutting data shows that a C45 unalloyed medium carbon steel bar of 250 mm diameter can be sawn with TCT in 2.5 minutes, while a similar diameter of stainless steel takes less than 7 minutes.

Not only is productivity raised but so also is blade life, which is between 10 and 12 m2 when cutting C45 and from 5 to 7 m2 when processing stainless. It makes the range of saws ideal for use in all industries, including those sectors processing difficult-to-cut alloys such as aerospace, nuclear, and oil and gas, as well as high volume production environments where cutting is typically two to three times faster than when using conventional bimetal bandsaws.

Additionally, recent expansion of bandsawing products to include the KASTOmiwin twin column, double mitring model in semi-automatic and automatic versions, plus the KASTOmicut pivot-bow mitre cutting saw for the workshop, is evidence of the company’s intention to strengthen its presence in the construction industry with a more comprehensive, single-source offering.

Another area of ongoing concentration in the R&D department in Germany is the manufacturer’s Industry 4.0 programme for digitalisation and networking centred on proprietary integrated control systems and interfaces. With KASTOlogic, for example, the company offers a modular warehouse management system tailored to the storage of long goods and sheet metal. The system transparently maps all the processes between goods receipt and product dispatch, ensuring efficient control over material flow.

Customised interfaces range from SAP, Infor and Microsoft Dynamics products to customer-specific software solutions, allowing easy connection to a higher-level host system. Even manually-operated warehouses can be managed through the KASTOmobile app, while the latter also allows monitoring of sawing machines to access data on cut length, target number and actual quantity, feed rate and cutting speed.

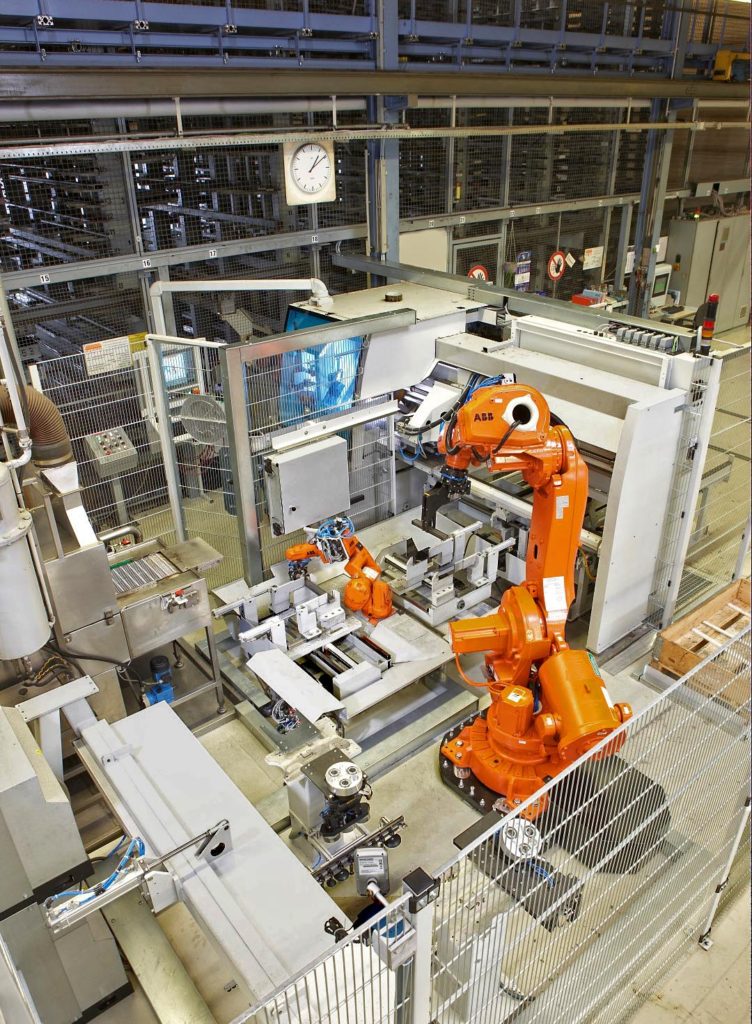

Kasto also has solutions to integrate and automate production processes upstream and downstream of the sawing process – the KASTOsort robot. Industrial robots can not only sort and stack sawn parts but can also perform other tasks such as deburring, chamfering, centring, threading, marking and printing.

KASTO’s VisualAssistance online system speeds fault finding and maintenance by a customer’s own personnel. If smart glasses are worn, the person has their hands free to carry out instructions given by helpdesk staff.

KASTO’s VisualAssistance online system speeds fault finding and maintenance by a customer’s own personnel. If smart glasses are worn, the person has their hands free to carry out instructions given by helpdesk staff.

Mr Wagner concluded, “With all this technology and back-up, our customers can make their manufacturing processes more flexible and efficient as well as benefit from optimal utilisation of machines, short non-productive times, reduced maintenance costs, lower production costs and other advantages. The quality of manufactured goods is higher than ever before and operating errors are virtually eliminated. “The end of political turmoil in Westminster is nigh, we all hope, and whichever side of Brexit you are on we should soon have certainty. Our customers and indeed all manufacturers should not forget that there is significant demand, both at home and especially abroad, that will lead to substantial opportunities for sales and exports. Let’s make 2020 a year of consolidation and of continuing to Make it in Britain.”

Source: Wire And Tube News www.wireandtubenews.com