Visitor Registration Opens in May 2026!

Fully automated material handling technology enters the tube fabricator arenaLaser processing of tubes and profiles has been one of the fastest-growing areas of metal fabrication during the past decade. It’s easy to see why. The tube laser allows fabricators to simplify part design and eliminate an array of time-consuming manufacturing steps.

Still, walk onto a shop floor with a tube laser and there’s a good chance you’ll see the machine sitting idle. Why? Because it’s waiting for material.

Taking the broader, order-to-ship view, laser tube cutting still makes the entire operation extremely efficient. It can simplify or eliminate numerous downstream manufacturing steps, so some machine downtime for material handling is a small price to pay. But material loading technology for the tube laser has evolved significantly. For many laser tube operations, extensive downtime for material handling might soon be a thing of the past.

The Business Case for the Tube Laser

Tubular product designs have many benefits. Metal tubes have a very high strength-to-weight ratio, creating structures and frames that can stand up to demanding usage without the need for heavy, expensive construction.

But tube and profile fabrication, especially using conventional techniques, comes at a cost. Utilizing conventional manufacturing techniques such as saw cutting, boring, milling and deburring is time consuming and expensive. To make even a simple tubular frame component with conventional methods can require many steps. These include measuring and positioning the raw material for sawing; fixturing the workpiece for each hole to be manually drilled on a drill press; clamping the cut-and-drilled piece onto a workbench to tap holes for fasteners; and even loading the part into a milling machine to add features such as notches and windows.

Between each step are the handling and temporary storage costs. All this requires significant labor and long lead times, creating high potential for mistakes and mishaps (read: waste). It also ties up significant amounts of factory floor space.

Lasers can cut extremely complex contours, creating tubular parts with a highly aesthetic, unique appearance. They also create interesting opportunities to reduce product costs.

For example, if you need to make simple 90-degree metal brackets, you’d usually cut the flat blank on a laser and bend them at a press brake. If you want to speed the process, you might cut a few brackets attached to each other by break-away tabs so that the press brake can form several at once.

Laser tube cutting, though, creates another option. The tube laser can cut a bracket shape out of a square or rectangular tube, with the “bend” in the bracket cut out of the corner of the tube. The tube laser, able to cut complex shapes quickly, could easily eliminate an entire manufacturing step. Brackets could emerge from the laser ready for finishing and final assembly, bypassing the press brake department altogether.

The tube laser can tackle the processing steps of positioning raw material, trimming, notching, creating internal features like holes and windows, beveling edges to prepare them for welding, and even adding threads for fasteners. In many cases, every manufacturing step to get from raw material to the finished tube component can be accomplished by one laser tube cutting machine.

Figure 1 A laser tube cutting machine has conveyors where operators can grasp parts for sorting. Parts can also drop directly into bins, which can be taken to the next manufacturing step. Photo courtesy of EMIT Technologies in Sheridan, Wyo.

In some instances, a laser can cut a geometry in a tube or other 3D shape that can actually be bent by hand. Think of a thin-walled rectangular tube with a cutaway, shown on a print as rectangular when viewed overhead, V-shaped when viewed along the sides. An assembler can bend this tube by hand to a specific angle, determined by the V shape. The tube wall material at the bottom of the V effectively becomes an outside radius in the final assembly.

And this is just a start. With the tube laser’s ability to add aligning and interlocking tabs and slots onto parts, the whole bent assembly could be welded with little or no fixturing, dramatically reducing both the welding time and the chance for errors and rework.

Evolution of Laser Tube Cutting

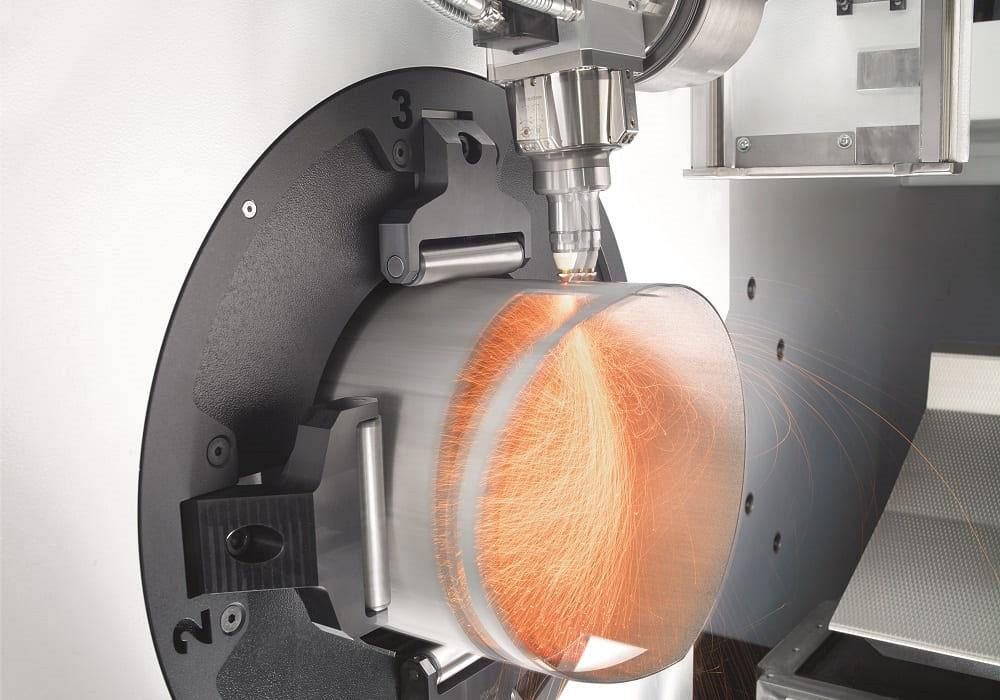

The earliest iterations of these machines were not much more than a CNC rotary chuck positioned beneath a laser cutting optic identical to the ones used for sheet processing. They were a big step up over sawing and milling but still limited in the scope of parts that could be made.

Over the past two decades, the state of the art has evolved. Tube laser optics have become more specialized and refined, allowing for finer processing and opening up the equipment to a wider range of raw material shapes, such as flat bar, channels, structural steel, and even extrusions. Tube lasers today can bevel-cut, thread holes, and locate and automatically orient weld seams.

Offloading Considerations

Tube lasers offer several offloading options. Conveyors can gently offload parts with cosmetic requirements. In batch production or one-piece-flow situations, the conveyor lets a machine operator quickly and ergonomically sort parts coming off the machine.

When minor scratching isn’t a concern, the machine can unload parts to a bin or basket. This saves space and helps manage delivery of finished tube parts to the next manufacturing step (see Figure 1).

The Loading Challenge

Material offloading from the tube laser can be quick and efficient—but the same can’t always be said for material loading. Raw tube stock can be between 20 and 30 feet long and weigh a few hundred pounds, so staging and handling obviously can also be unwieldy.

Many laser tube cutting operations use a lot of floor space to handle and move the material. Moving raw material often requires a crane, which is not only slow but also a safety hazard. Odds are that the laser will spend a fair amount of time sitting idle, waiting for tubes.

The automatic tube loader addresses these problems and makes the provisioning of raw material to the machine more compact on the floor, safer, and faster (see Figure 2). The system receives a bundle of raw material, separates individual tubes, and delivers them to the rotary chuck on the tube laser. A loading device takes the huge time savings already provided by the tube laser and multiplies it.

Automatic bundle loading does come with some limitations, however. Once a bundle of raw material has been placed in the loader, it needs to be emptied before switching over to new material (see Figure 3). Some loaders include a secondary raw material conveyor that bypasses the bundle space and allows a few sticks of various tubes to be inserted into production. But this is a manual process and feasible only for small batches.

If the operation needs to switch profiles often, a fork truck or crane operator will need to keep loading and emptying the bundle space. Even if the tube laser runs the same material for long periods, the bundle space will limit how long the machine can run before a crane operator or lift truck driver needs to reload it.

Walk through any factory today processing tube or structural material with a rotary laser and the picture will be the same: Automatic processing occurs only as long as a single bundle of tubes lasts. Beyond that, work comes to a halt, and employees must intervene to deliver additional material.

Figure 2 An automated loader separates a bundle of tubes and delivers them into the machine’s rotary chuck. Photo courtesy of EMIT Technologies in Sheridan, Wyo.

Automated Storage and Retrieval for Tube

A tube processing operation that switches between jobs without excessive wait time, or achieves maximum uptime on long-running jobs, requires another level of automation. Instead of loading the tube cutting process one bundle at a time, a fully automated system needs a direct connection between the tube laser and an automated material storage and retrieval system.

The latest equipment advancements make this kind of automation a reality. It is now possible to completely automate the tube laser process chain from material storage to finished part drop-off. Vertical storage systems designed around tubular raw materials are paired with an automatic crane and shuttle table. These work together to deliver various raw materials to a tube cutting laser on demand (see Figure 4).

Floor space tends to be at a premium in most factories, and even if it’s not, constantly shuffling pallets around the floor is inherently wasteful. Vertical storage eliminates that waste. Unlike flat stock, tubes and profiles do not exactly stack neatly. And when employees move these oversized, heavy loads—be it with a crane or lift truck—they introduce all sorts of hazards as they transport the awkward material.

There’s an obvious benefit in moving this unwieldy material to an automated shelf system. Tower storage systems also tend to simplify inventory management, providing quick transparency on the current stock levels for raw materials.

Such automation reduces setup and handling time at the tube laser. Being able to switch materials on-the-fly according to a production plan means that the tube laser now can be just as flexible and adaptable as any other automated machine tool. Greenlight time now can approach 100 percent, and the more minutes over a shift a fabricator can keep the tube laser adding value rather than sitting idle, the more profitable the operation will be.

Tubes in Motion

Much of the savings from laser tube cutting comes from reducing indirect costs inherent in conventional sawing and drilling: measuring, locating, handling, fixturing, stacking, and all the other steps people perform to get tubular parts through production, as well as the floor space requirements and inventory costs all this creates. These savings have made laser tube cutting a true success, providing benefits that far outweigh the challenges, including downtime related to tube loading.

For many applications, automatic tube storage and retrieval systems eliminate this final challenge. Integrated with the tube laser, they help manage the inventory of raw material and deliver it as needed to the tube loader. Automatic tube loaders measure the incoming material dimensions precisely and feed one stick at a time into the rotary chuck of the machine.

The tube laser itself nests and orients components within the stick for maximum material efficiency and creates all the needed features on the parts, including extruded and tapped holes. Parts then are separated from the stick and are deposited onto a conveyor or bin, ready to move on to the next manufacturing step.

Figure 3 Automatic tube loader with part separation is ready to be loaded with a new bundle of tubes. Photo courtesy of EMIT Technologies in Sheridan, Wyo.

Automated tube storage systems have some limitations depending on weight and material shape for automatic loading onto the tube laser. But in many cases, these limitations far outweigh the benefits such automation provides. Eliminating downtime, it closes the manufacturing chain for tubular and structural components, from start to finish.

As one of the Asia's most influential tube and pipe industry event, Tube China has been devoting to the steel pipe industry for many years. The exhibits include raw materials, pipes and fittings, tube manufacturing machinery, rebuilt and reconditioned machinery, process technology tools and auxiliary machinery, pipeline and OCTG technology, profiles and machinery, etc. It also provides support for coherent measuring and control technology, testing engineering and other specialist areas. Tube China 2020 will be held at the Shanghai New International Expo Center from September 23 to 26, 2020.

Source: the fabricator