Visitor Registration Opens in May 2026!

Tube cutting technologies advance to process with harder materials, stricter quality demands, and competitive pressures

Lasers that handle tubing and structural elements come in quite a few varieties. Among the most common are machines that grip long tube lengths with chucks and handle the most common tube and pipe sizes, up to 4 in. OD or so. Large-format machines include BLM GROUP’s LT24, which cuts diameters up to 24 in.; Bystronic’s M4 series, comprising the FL400 and FL600, which also cuts diameters up to 24 in.; Mazak’s Fabri Gear 400 II, which handles diameters up to 16 in.; and TRUMPF’s TruLaser Tube 7000, which cuts up to 10 in. dia.

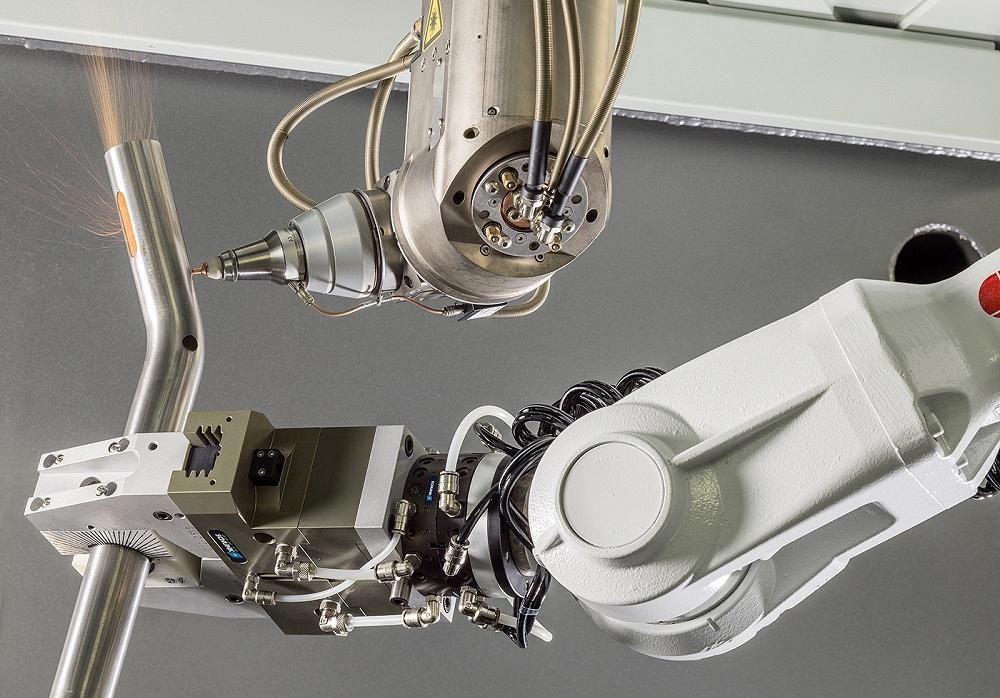

Still other machines are made for cutting short lengths of tube, such as bent tubular assemblies, hydroformed tubular components, and other 3D shapes. Two such machines are Mazak’s VCL-T100, BLM GROUP’s LT-Free, and TRUMPF’s TruLaser Cell series machines.

Accommodations for Tube. In the early days of laser cutting sheet material, sheet products often weren’t flat enough to optimize the process. When the torch moved over the surface of a standard-sized sheet from one end to the other, the distance from the torch to the work surface varied too much. The steel industry adapted, and before too long, the commercial standard for sheet flatness improved to accommodate laser cutting.

Tube is a different product, made a different way, and used in a different industry segment. The tolerances are different, too.

“The industry norms for tube are less strict in dimensional deviations than for sheet,” said John Quigley, vice president of marketing for LVD Strippit. “Tube fabricators need laser systems that can handle substantial variations.”

Cutting programs are based on ideal dimensions, but tube and pipe products are rarely straight, and nonround products often exhibit some amount of twist. For accurate cutting, and to prevent collisions between the laser head and the workpiece, the machine has to determine the tube’s actual shape and position relative to the cutting head and then compare it to the expected shape to compensate for dimensional variations. LVD Strippit machines use an onboard laser measurement system to measure bow, and they compare the chuck positions to the steady rest positions to determine twist. To optimize the tube orientation relative to the weld seam, the company’s laser machines use an optical system based on the inputs of two cameras.

Pioneering loading system versatility, LVD Strippit’s machines were the first to have two loaders on one machine, one for bundles and one with a seven-position magazine for loading individual tubes. Having an automated bundle loader on one side of the machine and a single magazine loader on the other side gives the operator the best of both worlds. When using the bundle loader for a production run, he can interrupt that job and load a few tubes one by one to fulfill a rush job, then resume the first job.

Likewise Bystronic devised a loading and unloading strategy that speeds up processing. Its machines use four chucks, but processing a tube doesn’t require all four chucks all the time.

“While the laser head processes the last features on one tube, using the first two chucks, a second tube is loaded into the machine using the final two chucks,” said Brendon DiVincenzo, product manager of lasers and automation for Bystronic Inc. It also uses mandrels that float, allowing the machine to accommodate the bow and twist of an individual workpiece, while putting less stress on the chucks and increasing precision in the cutting zone.

TRUMPF’s TruLaser Tube 7000 also offers a few additional features that expand the possibilities in processing tube. Additional tools provide tapping for holes in heavy-wall tube and friction drilling and tapping for thin-wall tubes. It also has an optional mandrel that slips into the workpiece to protect the ID from spatter generated by the cutting process.

Big Diameters, Heavy Walls. Mazak Optonics Inc. estimates that the use of structural steel is projected to grow at 5.3% compound annual growth rate over the five-year span from 2018 to 2023. The drivers it cites are the federal government and the construction industry. The former deals with infrastructure and the latter concerns both residential and nonresidential construction. Two factors that favor laser-cut steel tubing for such applications are recyclability and speed of construction. About 90% of metals are recycled, and precise laser cutting facilitates fast joining.

A laser machine’s precision in making countersunk holes for fasteners, miter cuts for joint connections, and beveled ends for weld prep makes jobsite assembly and welding go faster than it would using conventional processes.

For such applications, Mazak’s machines provide six axes of control and four self-centering chucks to deal with the dimensional inconsistencies of tube and profile such as hollow structural section, I beam, H beam, and angle. The company’s direct-diode laser technology is 45% more energy-efficient than CO2 lasers and has 40% more power density compared to fiber lasers, according to Mazak.

To adjust to various workpiece geometries, TRUMPF’s machines use a self-centering collet chuck to prevent tube damage. The clamping system is combined with a sensor that provides continuous monitoring to make any necessary changes in the laser head’s path to prevent collisions.

BLM GROUP USA recently introduced its LT8.20, which has 3D capability and handles essentially any shape. It was designed to handle complex cutting patterns, hard-to-reach locations, and weld prep cuts on thick-walled tubes. It uses three features in the company’s Active series: Active Tilt for fast processing of small features; Active Weld, designed to optimize scrap detachment with large weld seams; and Active Focus, which handles changes in material and thickness.

Configuring the system with the chain loader on the front side reduces the system footprint by 20% and enables loading and unloading operations from the same side. This makes the system even more efficient for small-series production and small quantities.

CO2 or Solid State? In the laser arena, the CO2 laser is giving way to solid-state technologies. For the most part, this means fiber lasers, but TRUMPF has its proprietary TruDisk and Mazak has a direct-diode laser. Known for simplified beam delivery and much lower maintenance requirements than the CO2 variety, solid-state lasers provide more uptime and are less expensive to maintain. But this doesn’t mean that CO2 lasers are on the way out.

“Market demands for fiber lasers are growing, but CO2 lasers still have a place in manufacturing, just not the dominant one they had in the past,” DiVincenzo said. It’s not just a matter of replacing a resonator. The fiber laser light frequency is such that the machine design is quite a bit different from that of CO2 resonators. Fiber lasers need a completely enclosed cutting area, which can make loading and unloading material more complicated. The generally accepted performance advantages of fiber technology just don’t apply when cutting very large workpieces.

“The logistics of material handling are better for CO2 lasers,” he said.

As the previous exhibitor of Tube China, TRUMPF has presented its manufacturing solutions in the fields of tube processing machines and technology. Industry colleagues and buyers are looking forward to TRUMPF’s participation in Tube China 2020, Asia’s leading tube and pipe exhibition again. The tube expo will take place on 23-26 Sept. 2020 in Shanghai China.

Related Articles:

TRUMPF’s TruLaser Tube 7000 fiber laser processes extra-large tube

TRUMPF acquires Laser Diode Division of Philips

TRUMPF benefits from e-mobility