Visitor Registration Opens in May 2026!

Schwarze-Robitec delivers efficient tube bending machine to ELB-Form

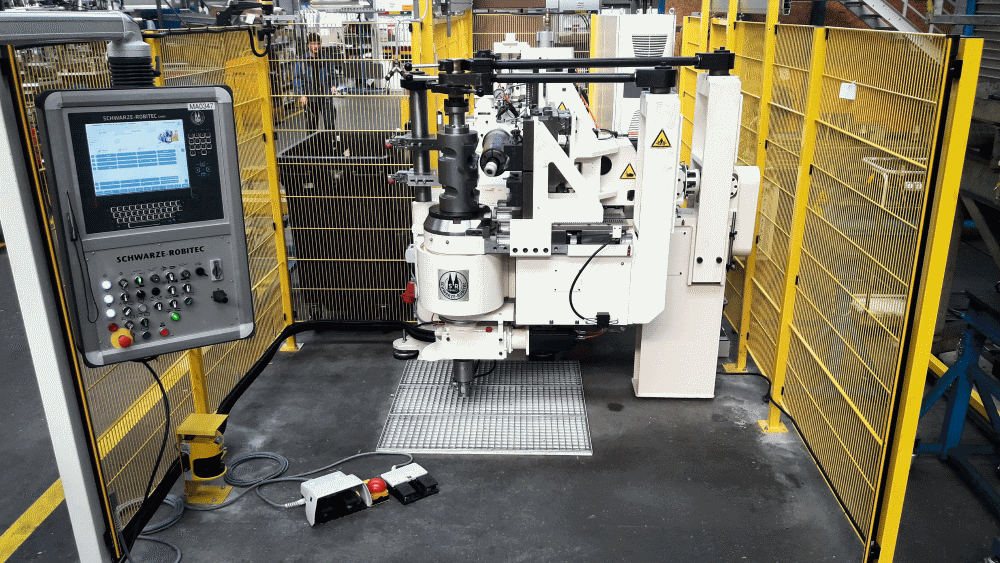

The new CNC 80 E TB MR enables an enormous reduction in production time for Schwarze-Robitec’s long-standing client, ELB-Form. © Schwarze-Robitec GmbH

For the Austrian company ELB-Form, a simple order for a new machine from Schwarze-Robitec ended in a huge increase in productivity and efficiency. The fully electric multi-radius tube bending machine CNC 80 E TB MR is ensuring extremely short cycle times for the experts for cold and hot forming. The key to this productivity gain is Schwarze-Robitec’s intelligent NxG control system. Production time is reduced by 20 to 40 percent depending on the component and the desired tube geometry.

Extremely tight tolerances even with complex tube geometries for confined spaces – for the production of exhaust tubes and systems, ELB-Form, an Austrian company based in Vandans (Vorarlberg), meets the high requirements of its customers from the automotive and aviation industries, among others. Tube bending expert Schwarze-Robitec designed a CNC 80 E TB MR for their loyal client, albeit with one crucial difference to the machines they were already familiar with: ELB-Form is now using a tube bending machine with NxG control for the first time.

From 35 to 16 seconds: Saving time while bending

For each bending sequence, the system automatically checks the interaction between all axes and ensures the movement sequences are optimally coordinated. This means that whilst a bending process is ongoing, the axes are already being prepared for the next sequences. The production time is reduced by 20 to 40 percent depending on the component and the desired tube geometry – the more complex the geometry of the tube to be bent, the more time is saved. The factory acceptance test carried out for the machine demonstrated just how great the benefits really are for ELB-Form. For one particular application, the time required for a single bending process was reduced from 35 to 16 seconds. This is a major advantage for suppliers in the automotive industry, where turnover times are key.

The new machine is also helping ELB-Form to reduce production time thanks to faster tool changing times with the Quick-Tool-Unlock system for a quick and easy assembly and disassembly without any additional equipment. The system has a positive effect on the bending result, too. Users no longer having to adjust the tensions bars themselves – e.g. to make them tighter or looser – increases the level of repeatability and enhances process security. In addition, Schwarze-Robitec implemented a client specific log-in system seamlessly linking the machine to other internal company processes such as clocking in and out of work.

The Austrian experts have placed their faith in Schwarze-Robitec’s tube bending expertise for more than 20 years and have several CNC machines in use. Impressed by the increase in productivity brought about by the CNC 80 E TB MR, ELB-Form is now planning to retrofit the NxG control system for an additional machine in its inventory.

Source:Tube Dusseldorf