Visitor Registration Opens in May 2026!

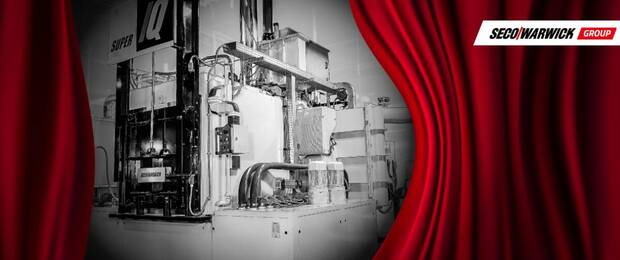

Super IQ was designed specifically to eliminate the need for endogas, and its inherent flames and carbon monoxide dangers. Instead, Super IQ allows clean processing and can even achieve higher temperature carburising to speed cycles and improve yields in certain steels in a clean and cool manner. Parts also come out much cleaner and brighter.

“The Super IQ is a well thought out replacement to the traditional-gas-fired IQ furnaces. The technological advances allow us to run at higher temperatures, vacuum carburise, and clean harden with no decarburising effects. The fact that our existing systems fit perfectly with this new addition helps to minimise the overall investment and accelerate successful integration. We expect the Super IQ to reduce operating costs, improve safety, and enable more environmentally friendly processing”, says Johnathan Rex, General Manager at Rex Heat Treat.

A game-changer for gas carburising

Seco/Warwick engineers envisioned Super IQ to change the market, because it is an affordable successor technology in batch harden and quench markets. The furnace takes decades proven technologies and integrates them into a single system for easy implementation with standard quench oils.

"Our alternative to the integrated hardening furnace - i.e. the Super IQ - was created in response to the needs of heat treatment companies. The industry required a safer, cleaner, faster and more effective carburising method. Compared to traditional methods, Super IQ provides many benefits, but especially productivity improvements. It works in higher temperature ranges, which translates into shorter cycles with no reduction in furnace life. As a result, it delivers more efficient production for less. This is a game changer the world over,” commented Piotr Zawistowski, Managing Director of Seco/Vacuum, Seco/Warwick’s subsidiary.

Rex Heat Treat, with facilities in Lansdale and Bedford, Pennsylvania, and Anniston, Alabama, has been operating continuously since 1938. Over three generations, it has developed a progress model based on the use of innovation to meet their customers’ current and future needs. Because of this development strategy, Rex can effectively serve clients in demanding industries such as aerospace or space industry.

Source: Heat processing www.heat-processing.com