Visitor Registration Opens in May 2026!

High strength and nickel-free metal powder from Deutsche Edelstahlwerke

Deutsche Edelstahlwerke (DEW), a company in the SCHMOLZ + BICKENBACH Group, are expanding their portfolio for additive manufacturing. Printdur® HSA is a metal powder produced using gas atomization, which has an 99 % austenitic structure in its as built condition. As a consequence, the material is non-magnetic. It is characterized by significantly improved strength values and offers potential to be applied in many industries.

Printdur® HSA is ideally suitable for selective laser melting, also called laser powder bed fusion (LPBF). Accordingly, it can easily be processed on LPBF systems. Compared to typical austenitic steels, the material is characterized by a much higher yield strength, tensile strength and hardness. For example, although the material 1.4404 (316L) has established itself as the standard steel in additive manufacturing, but compared with Printdur® HSA it has a much lower strength level.

The yield strength and tensile strength of Printdur® HSA are twice as high. Last but not least, its high pitting resistance equivalent number (PREN) of 36 demonstrates the excellent corrosion resistance of the new DEW metal powder. In its as built condition, Printdur® HSA is corrosion resistant according to SEP 1877 method 2 (resistance test against intergranular corrosion) and ASTM G48 method E (resistance test against pitting).

Interdisciplinary opportunities

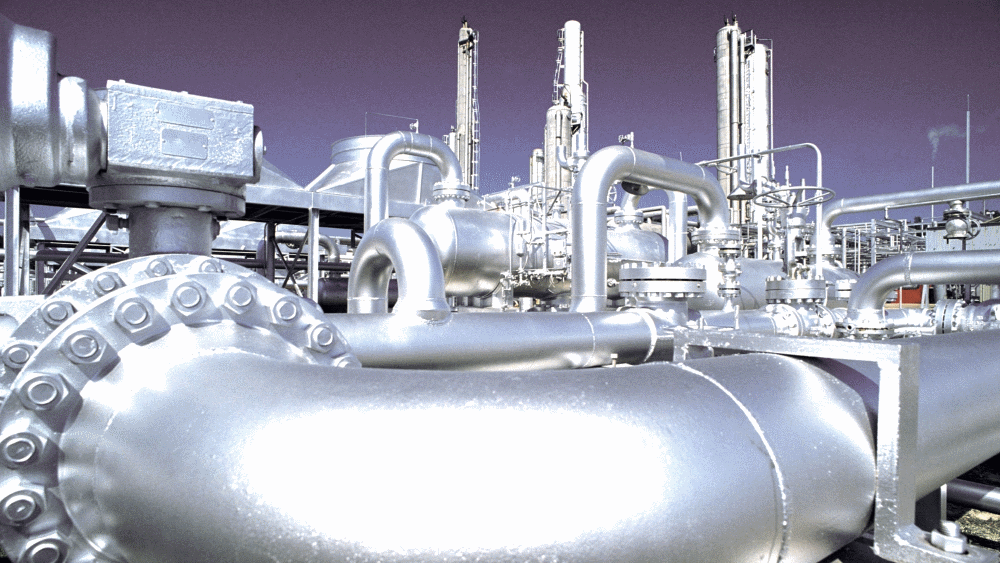

Due to the properties mentioned, a wide range of applications can be achieved with just one material: whether in mechanical engineering, for facilities in the food and chemical industries, pump components, the power plant industry or in the automotive industry.

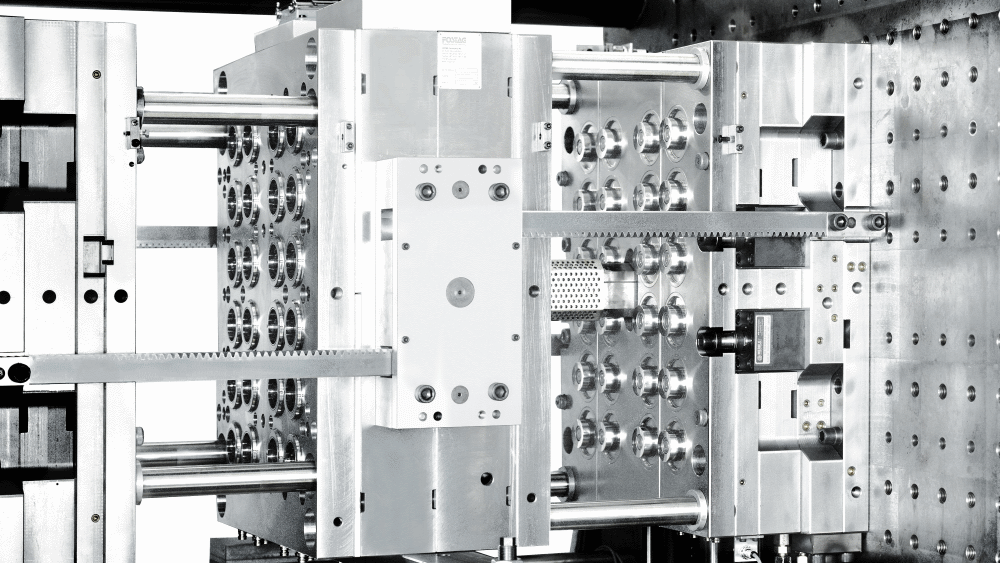

Although additive manufacturing is not able to replace classic mold construction, it can improve the efficiency of the production process. For instance, 3D metal printing provides benefits particularly in the manufacture of complex molds.

In addition, the construction of prototypes or the production of cores, cavities or inserts for tools, dies and molds can help in the manufacture of small batches. This is where design freedom and the short production time have a positive effect.

DEW customers part of the process chain

When it comes to developing the metal powder, DEW include their customers in the complete process chain: starting with the alloying idea and the production of the powder, to the ready-to-use prototype and component, ending with large-scale production beyond additive manufacturing.

DEW’s years of experience in the manufacture of metal powder for build-up welding comes to the fore here. The production takes place mainly at the plant in Krefeld and is certified according ISO 9001 (quality management systems) and IATF 16949 (automotive quality management). This means that DEW guarantees consistently high quality for all their powder materials produced in house.

Source:Tube Dusseldorf