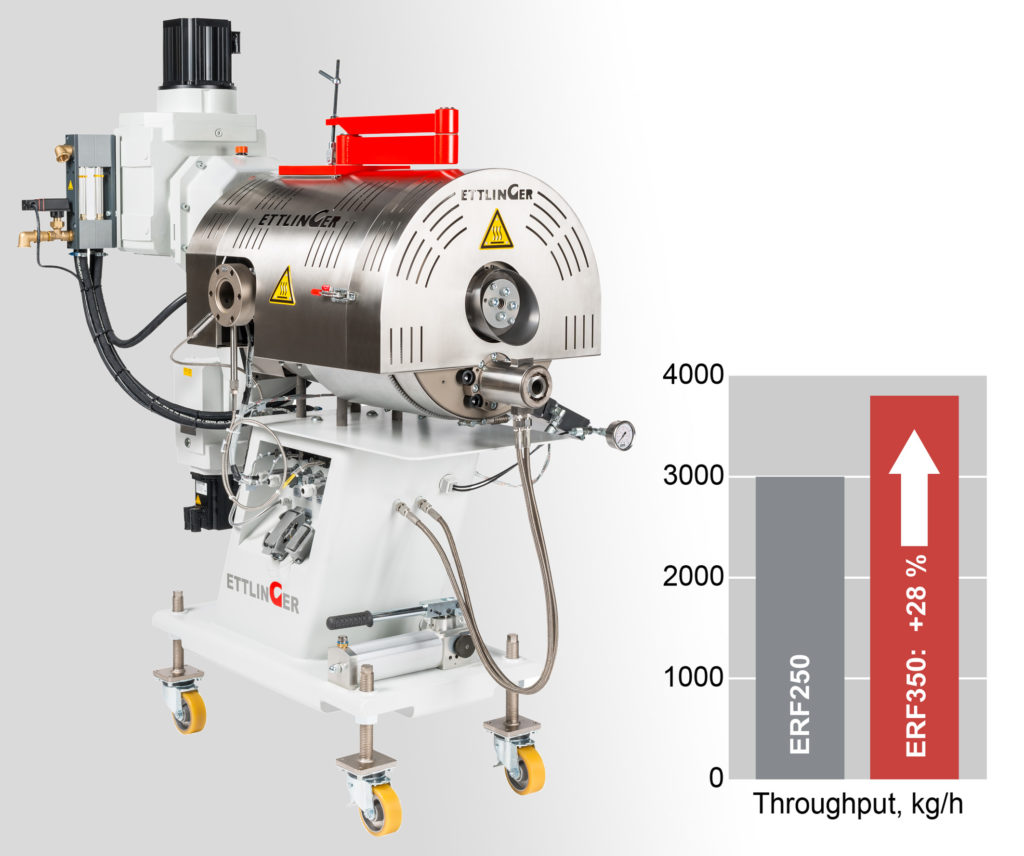

Depending on the type and level of contamination in the melt to be cleaned and the selected screen size, the ERF350 achieves a maximum throughput of 3800 kg/h in combination with the same ultra-low melt losses. It is thus positioned much higher up in the portfolio than the existing ERF250, which already impresses with a maximum throughput of 3000 kg/h. This represents an increase of around 28% for the same filtration surface and typical small footprint. This value has since been confirmed during the first few months of practical duty with pilot customers. Users profit from more productivity when recycling contaminated waste plastics from industrial or consumer sources. Furthermore, experience to date has shown that energy consumption is about as low as that of the ERF250 in spite of the far better efficiency.

Volker Neuber, Ettlinger's managing director: "Users of our new ERF350 melt filter very soon realize that their investment pays for itself in minimal time owing to the clearly superior performance. It's a highly efficient way for recycling plants to strengthen their competitiveness in terms of costs and performance in what is a fiercely contested market constrained by price tags. Companies which process large quantities will particularly profit from the new technology. Compounders where PP is converted for use in the automotive sector or manufacturers of, say, LPDE packaging films, are only two examples here."

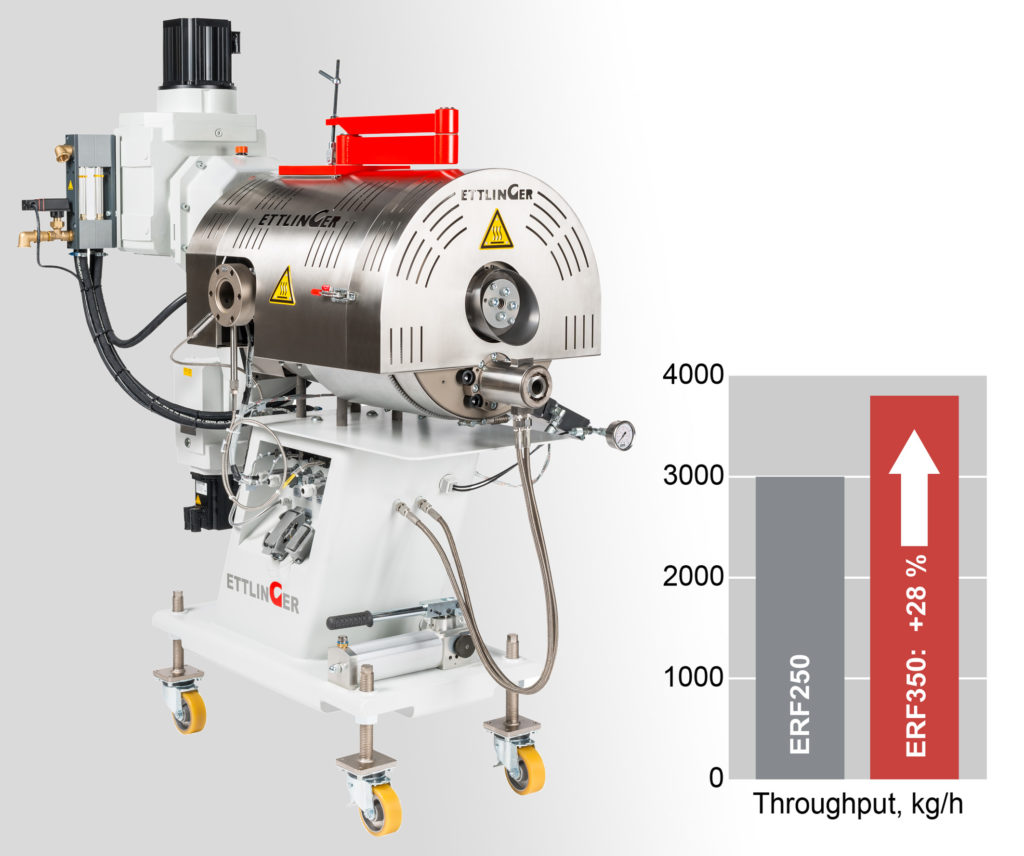

Like all ERF and ECO filters built by Ettlinger, the new, self-cleaning ERF350 model works with a rotating, perforated drum, through which there is a continuous flow of melt from the outside to the inside. The screen sizes range from 80 μm to 1300 μm. A scraper continuously removes the contaminants that are held back on the surface and feeds them to an exit screw or discharge shaft. This enables the filter to be used fully automatically and without any disruptions over a period of weeks and months without having to replace the screen. The advantages of this design are the constant melt pressure at the filter outlet leading to more reliable processing, ultra-low melt losses – recognized throughout the industry – and good mixing and homogenizing of the melts. Whereas the ERF series is optimized for separating foreign particles from heavily contaminated polymers, the ECO series is ideal for filtering polyolefins, PET and PA as well as recycled material containing up to 1.5% contaminants during the extrusion of films, sheets and other semifinished products.

Ettlinger Kunststoffmaschinen GmbH was founded in 1983 and is today a global player. The company has its headquarters in K?nigsbrunn, not far from Augsburg. A sales and service subsidiary opened in Atlanta (Georgia) in 2013. Its core competency is in the development and manufacture of injection molding machines and high performance melt filters. On the melt filtration side Ettlinger makes systems for continuous filtration of feedstock with varying degrees of contamination. Contaminants like paper, aluminum, wood, silicones or high-melting polymer composites can be removed from all standard polymer materials. Ettlinger injection molding machines are optimized for the production of polymer moldings up to 100 kilograms in weight such as plastic pallets, fittings, or manholes.

Source: Wire and Tube News