Visitor Registration Opens in May 2026!

Ever since entering into the seamless and welded tube market Danieli’s ambition has been to supply Customers comprehensive services and solutions capable of increasing business profitability.

Nowadays, the OCTG market is moving further and further away from API commodities to premium connection specialties, however fluctuations in tube demand and prices oblige seamless and welded tube producers to invest time and resources in contemporary and highly sophisticated products capable of meeting the requirements of new drilling scenarios. Short reaction times, efficient project scheduling and the employment of new technologies are preconditions for a rapid return on investments.

To ensure positive outcomes in the installation of new plants and finishing lines a main contractor managing all the phases of the production process can guarantee the quality of finished products by keeping the project schedule and budget under control. The target of Danieli W+K is to focus on the most critical operations involved in tube finishing in order to achieve this goal.

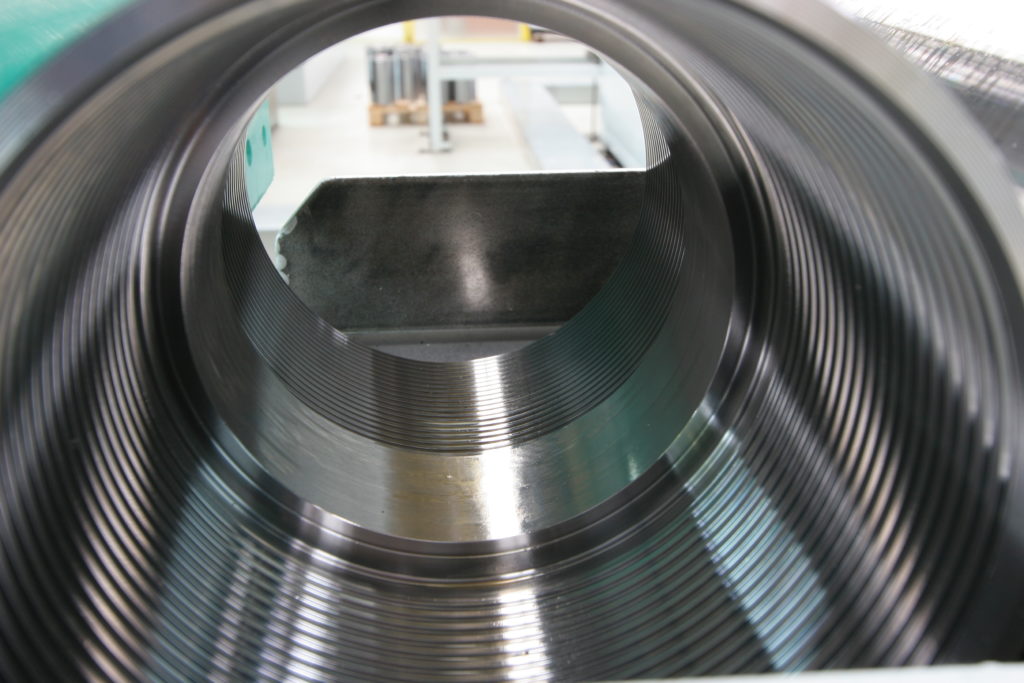

Danieli W+K entered this field with a breakthrough technical solution, performing large-scale industrial testing of the new Danieli PcTM-13 premium coupling threading machine with advantageous results. API and premium couplings with 98% machine availability and 93% of good pieces with dimensional tolerances within 25% of API standard tolerances were produced right from the beginning.

A central drive configuration for the manufacture of premium connections in one step, avoiding multiple coupling positioning in the head stock was selected. This solution eliminates any possible deviation in concentricity at the extremities and enhances machine productivity.

The clamping force is distributed evenly on the coupling surface by 2 clamping planes and 12 jaws to prevent distortion particularly in the seal area and even where premium couplings with an extremely thin wall thickness are concerned. The machine can be easily integrated into an automatic coupling shop where blank roughing and finishing can be performed in series on 2 PcTM machines.

Heavy-duty design and high-precision positioning of the cutting inserts reduce the number of threading passes for API and Premium couplings and offer increased cutting speed and feeding.

High-pressure (up to 150 bar), properly directed nozzles enhance the life of the inserts and help control the threading chips. Dedicated adjustable flushing nozzles directly mounted onto the toolbars make it possible to remove the threading chips from the coupling efficiently at the end of each threading pass. A very smooth toolbar design eliminates manual intervention by the operator.

Further advantages of the PcTM design in terms of competitiveness are fewer rejected pieces with a high-precision machine capable of producing finished couplings with a tight range of dimensional tolerances required for high-end applications, less manpower, lower maintenance, reduced spare parts and tooling inventory.

Customers interested in viewing the PcTM-13 machine in operation and in testing their premium connections are welcome to visit the workshop in Brescia, Italy.

At Danieli W+K, we consider the PcTM-13 an important step forward in the development of our threading technology. However, we also acknowledge that only our end users can suggest how to push the performance of our new machine to its limit.

We are already working on variants, improvements and customizations of the PcTM design while our technical team is developing a new 4-axis rotating tube threading machine complete with threading table.

Our mission in this challenging market is to support our customers in accomplishing their goals, which are high profitability and reduced investments. The PcTM-13 premium coupling-threading machine is designed for and achieves these targets.

Source: Wire & Tube News