Visitor Registration Opens in May 2026!

Volker Bühler, group manager for robotics at German sawing machine and storage system manufacturer, Kasto, describes the widening choice of automation systems on offer to minimise labour costs and increase production output from the company’s circular sawing and bandsawing machines. The production solutions are available in the UK and Ireland through the firm’s subsidiary in Milton Keynes.

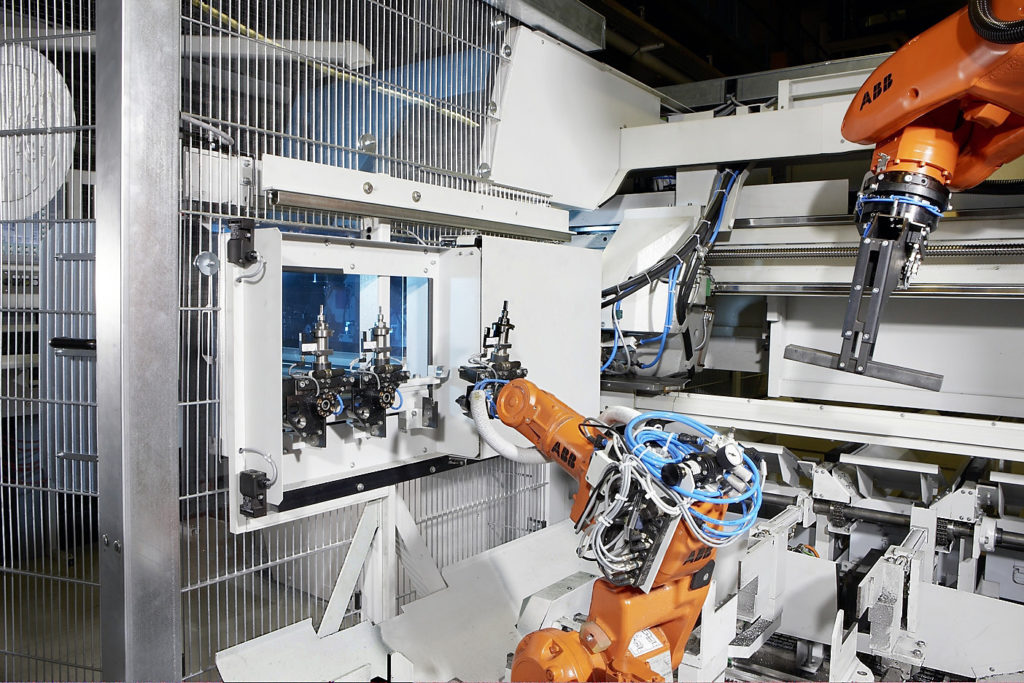

Industrial robots make production more flexible and efficient, from batch sizes of one to large volumes. They also improve working conditions for operators and can significantly reduce costs in stockholding and manufacturing operations. More and more, operators of sawing systems are automating them with robots, as they are fast, reliable, precise and if necessary can work continuously 24 hours a day without human intervention.

Robotic systems are taking over numerous process steps following sawing, starting with removal of the cut pieces, continuing through deburring, chamfering, measuring and marking and on to weighing, sorting and stacking on pallets or in containers. The parts can be transferred to a driverless transport system and taken elsewhere in a warehouse or factory.

Automation starts with material feeding. Stock to be cut can be supplied to a machine by means of a roller conveyor or magazine, for example, sparing workers the effort of lifting and reducing the risk of injuries. Depending on how it is equipped, the sawing machine can run attended, with the control system holding all parameters of a job including material diameter, band speed, rate of downfeed, cut length and number of parts.

Mr Bühler commented, “In complex processes involving numerous work steps, we use combinations of different robots, grippers and other end effectors.

“When large quantities of material with only a few different component geometries are sawn, it is relatively easy to automate the downstream processes.

“The situation is different with custom sawing involving diverse materials and dimensions. The greater the variety, the more difficult it is to cover all the possibilities.”

He explained that end-of-arm tool selection is an important factor. A robot must be able to deal with all the objects it encounters while using as few attachments as possible. It reduces procurement costs, minimises idle times and increases productivity. Users have a choice of mechanical, magnetic or vacuum grippers, which should be as compact as possible to give the robot easy access to the cut parts.

With the help of the right components, sawing can be combined with other automated operations to create complex, highly integrated systems that are seamlessly connected by continuous material flow. It includes upstream storage as well as downstream handling.

Kasto can implement combined storage and sawing systems for its customers in which all processes are automated, from storage of the raw material to retrieval of the cut parts. The control software can be linked to existing ERP systems for greater transparency and efficiency. Sawing can even be integrated with other processes like turning or milling within a digitised, Industry 4.0 production environment.

Mr Bühler continued, “With automated sawing technology, companies can react more easily to order peaks and dramatically reduce idle times. It can make a big difference economically.

“We have calculated that, depending on shift model, investment in an industrial robot with a machine like our KASTOvariospeed circular saw can pay for itself in less than a year.

“When you consider that such systems are used for more than ten years on average, users can reduce their operating costs for a very long time.”

Robot technology also helps to improve working conditions. It relieves employees of heavy, tiring and monotonous tasks and the risk of accidents and injuries is reduced. Moreover, the cut parts are of better quality because robots process them with equal precision, sort them reliably and stack them neatly. The latter is particularly beneficial if subsequent operations on the parts are automated.

Source: wireandtubenews