For the past 30 years transfluid has been shaping progress in tube processing

When people think about 1st April they mostly think about spectacular stories that ultimately turn out to be a joke. That is not the case for Gerd N?ker and Ludger Bludau. They both remember how the history of their company also started on a 1st April and now, 30 years later, the success it enjoys is greater than ever. The story is about transfluid: established in 1998 in Schmallenberg in Sauerland as a two-man business, the current GmbH is now a sought-after international partner providing solutions for machines to bend and process tubes. Since 2013 it is also a world market leader in CNC-controlled rolling tube forming. There is very little now to remind us of those humble beginnings, when there was just 125m2 available. But there is one aspect that transfluid has remained true to for the past three decades: its commitment to progress in tube processing for the benefit of its customers.

Always one step ahead

Always one step ahead

When you walk through transfluid’s production halls in 2018 you will see fully automated production units and robots, working efficiently and accurately as bending and end forming systems. “When we started out in 1988 the internet was not playing a role yet and I am sure that nobody could have predicted how digitalization would revolutionize whole industry sectors on such a massive scale and in the shortest of time – including tube processing, of course”, says business co-founder Gerd N?ker. In spite of that, the first development that transfluid – still N?ker & Bludau oHG at the time – launched on the global market was a small sensation. This was, after all, the first manual tube bending machine for small tubes, up to 16mm diameter; the t bend MB 642 is the unparalleled top seller and it is still requested from all over the world for on-site jobs.

The solution for tubes

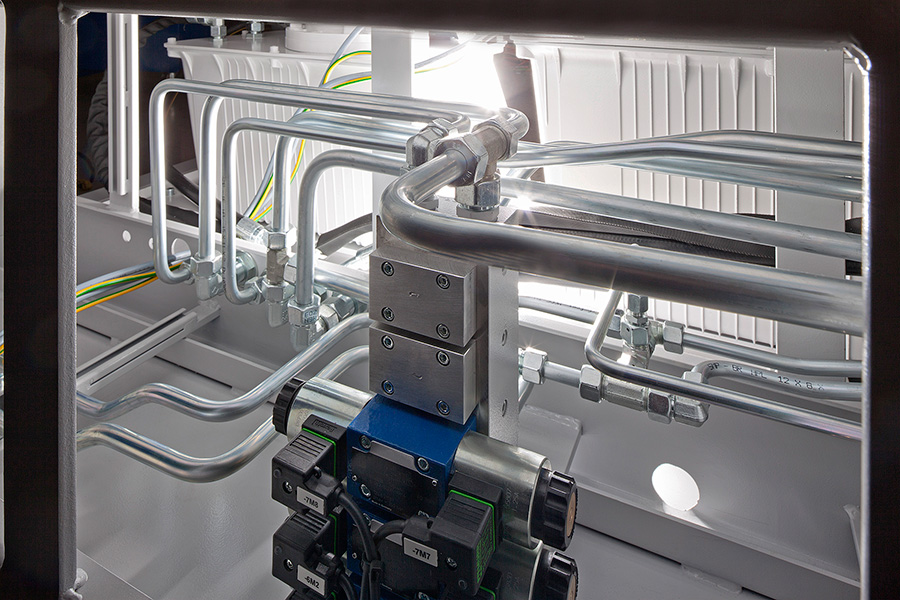

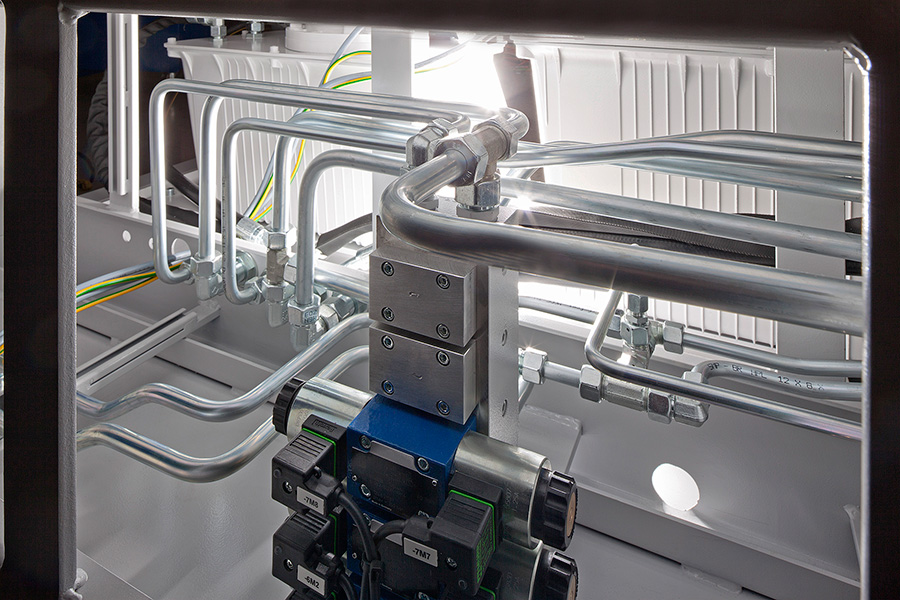

There are now more than 12,000 machines in circulation globally, shaping tubes according to the concept of Bestform. transfluid is “the solution for tubes”, whether it is end forming, bending, cutting or connecting of the machines to an automatic cell. With their traditional technical creativity, the experts are, of course, also developing fully-automated solutions, including customized solutions to meet their customers’ individual requirements. The client base comes from a number of sectors: the plant and machine construction sector is represented just as strongly as the automotive and energy industries and shipbuilding, as well as many more. Ludger Bludau points out that “this is exactly what still makes our work so exciting after 30 years. We have the opportunity to grow again and again, together with our customers, thanks to the new challenges, and thus redefine the boundaries of what can be achieved in tube processing”. Greater efficiency, flexibility and optimized processes: transfluid offers all of this with its smart software, into which the experts have packed all their know-how. The comprehensive portfolio is completed with a wide choice of stock machines, offering fast delivery prompt support to deal with everyday challenges.

Strong team and entrepreneurial vision

A lot of room is needed for so many ideas and transfluid has created this over time. In 1991 the business found a new home at the current site in Schmallenberg. In addition to that, the business’ leadership has grown from two to five proud members. Benedikt Hümmler, Burkhard Tigges and Stefanie Flaeper have further strengthened the Bludau and N?ker founding duo. With their combined strengths and strategic vision, the leadership group of five keeps the business on the road to success, supported by a strong and committed team. It is noteworthy that there are 10 employees who have known the business since the beginning and are still working for transfluid.

Global market leadership leads to knowledge exchange

Global market leadership leads to knowledge exchange

transfluid’s position as an international market leader through its technology was confirmed in 2013 in a special way. With the newly developed CNC-controlled incremental tube end forming, the business was added to and is still included in the “List of global market leaders” of the South Westfalia Chamber of Commerce. Highly complex moulding geometries can now be achieved with the novel rolling process, such as end forming with very strict tolerances, groove structure with sharp edges and polished surfaces. This kind of forming are independent of special dies because they are adjustable. “We are of course proud of this recognition, as it is the result of intensive development work, into which a lot of our know-how has been poured”, says Stephanie Flaeper, managing director at transfluid. “However, it is also important for us to share this knowledge in the interest of advanced developments.” Therefore, the company regularly invites other experts to exchange experiences and thoughts at its Innovation Days. The experts meet once a year in Sauerland, to learn about the latest developments and to discuss the challenges of tube processing together. One thing is always clear during these events: transfluid will continue to chart new routes over the next 30 years.

Source: WIRE AND TUBE NEWS